Asko dishwashers have become essential appliances in modern homes. However, they can sometimes encounter technical issues, and it is important to identify and resolve these problems. Asko dishwasher error codes serve as a valuable source of information for users to diagnose issues and intervene when necessary. In this article, we will explore the meanings of Asko dishwasher error codes and their possible solutions. By doing so, you can enhance the performance of this advanced appliance, make the user experience smoother, and minimize the need for repair services.

Most Common Codes

| Error Codes | Solution |

|---|---|

| F1 | Temperature stop fault. The temperature rise is less than 5°C in ten minutes. Check: Element, thermistor, water level, circulation pump and control unit, wiring. |

| F2 | Overfilling. Too much water in the machine (pressure sensor) or float activated. Check: Drain pump (blockage in hoses), flow sensor, inlet valve, leakage, wiring. |

| F3 | Thermistor fault. Interruption or >80°C. The programme exits from the heating stage and continues in the process. Indication only in the service menu. Check: Thermistor, control unit. |

| F4 | Water intake fault. < 80 pulses within 60 seconds or correct number of pulses is not achieved within 255 seconds. Programme interrupted. Check: Water supply, flow sensor, inlet valve, wiring. |

| F5 | Valve leakage. > 80 pulses detected when the inlet valve is deactivated. Certain models attempt to remedy the leak first. Any programme in progress is interrupted (drain pump activated). Check: Leakage through inlet valve, flow sensor. |

| F6 | Pressure sensor fault. Output signal > 4.8V. The programme continues. Indication only in the service menu. Check: Pressure sensor, control unit and wiring. |

| F7 | Pumping out fault. Water not evacuated after 120 seconds’ pumping out. Programme interrupted. Check: Drain pump, hoses, installation of drain hose, control unit and wiring. |

| F8 | Blocked filter. The pressure sensor senses excessively low pressure during the final rinse. Indication after end of programme. Check: Filter, sump (pressure chamber), pressure sensor. |

| F9 | Circulation fault. The pressure sensor senses excessively low pressure (e.g. no water in the machine) or excessively high pressure (e.g. the circulation pump is defective). Check: Circulation pump, filter, water level, pressure chamber and pressure sensor. |

| F10 | Overfilling. Check Drain pump (blocked hose), flow meter, inlet valve, leaks and cables. |

| F11 | Water outlet fault. Check Drain pump, hoses, drain hose fittings, control unit and cables. Also check whether filter is blocked. |

| F12 | Water inlet fault. Check Water inlet, flow meter, inlet valve and cables. |

| F40 | Inlet valve leakage. Check Leak through inlet valve and flow meter |

| F41 | Temp stop fault. Check Element, thermistor, water level, circulation pump, control unit and cables. |

| F42 | Thermistor fault. Check Thermistor, plugs, wire harness, and control unit. |

| F43 | Pressure sensor fault. Check Pressure sensor, control unit and cables. |

| F44 | Turbidity sensor fault. Check Water quality, filters, turbidity sensor and drain system. |

| F45 | Spray arm diverter fault. Check Spray arm diverter (functioning gearbox, switches and cables). |

| F52 | Water level fault |

| F54 | Overfilling water 2. Turn off the water supply valve. |

| F56 | Circ. pump fault. |

| FA | Turbidity sensor fault. Indication only in the service menu. The machine assumes high turbidity for “choice of route” in the automatic programme. Check: Water quality, filter, turbidity sensor, drain system. |

| FB | Spray arm divider fault. Position contact is continuously closed or open. The programme proceeds. Indication only in the service menu. Check: Spray arm divider (function of gearbox, contacts and wiring). |

| L6 | Rinse aid indication |

| L7 | Door open/Close door |

| Close the door | The door is open. Close the door. |

| Temp stop fault | Temperature increase less than 5°C (41°F) in ten minutes. Program continues with the process. Only indicated in service menu. |

| Overfilling | Overfilling. Too much water in the machine (pressure sensor) or float activated. If the water has not been emptied within 60 seconds, the program stops (drain pump activated). |

| Thermistor fault | Communication between the thermistor and control unit has stopped or the thermistor is reporting temperatures greater than 80°C (176°F). Program continues with the process. Only indicated in service menu. |

| Water inlet fault | < 80 pulses within 60 seconds or correct number of pulses not achieved within 255 seconds. Program stops. |

| Inlet valve leakage | Water intake detected when inlet valve deactivated in program sequence or standby. In this case the machine attempts to close the valve by opening it for 2 seconds and then closing it again. If water flow through the valve is still detected any current program is stopped (drain pump activated). |

| Pressure sensor fault | Output signal > 4.8 V. The program continues. Only indicated in service menu. |

| Water outlet fault | Water not drained after 120 seconds draining. Program stops. |

| Turbidity sensor fault | Only indicated in service menu. The machine assumes high turbidity in case of “uncertainty” in the auto program. |

| Diverter fault | Position switch always closed or open. The program continues. Only indicated in service menu. |

| Humidity sensor fault | “Humidity sensor fault” (only in service menu) Check Humidity sensor, cables, fan, damper and Wax motor. |

| Clean filter | The display indicates “Clean filter” automatically after every 300 cycles. |

Total Reset

To reset the machine to its factory settings.

- Turn off the main power switch (S5).

- Wait at least 5 seconds.

- Press and hold the program and menu buttons (S1 and S4).

- Switch on the main power switch (S5).

- Release the program and menu buttons (S1 and S4).

Troubleshooting

| Problem | Possible causes |

|---|---|

| The dishes are not clean. | The spray arms do not rotate. |

| Old detergent. Detergent is a perishable product. | |

| Incorrect detergent dosage. | |

| Dishwashing program too weak. | |

| Dishes loaded incorrectly. | |

| Glasses and cups have toppled over during the program. | |

| The filter is not correctly fitted. | |

| Spots or films on the dishes. | Incorrect rinse aid dosage setting. |

| The dishes have a sticky white/blue film. | Rinse aid dosage setting too high. |

| Spots on stainless steel or silver. | Some foodstuffs, such as mustard, mayonnaise, lemon, vinegar, salt and dressings, can mark stainless steel if left for too long. |

| Spots left after washing. | Lipstick and tea can be difficult to wash off. Use a detergent with a bleaching agent. |

| Rattling sound when dishwashing. | The dishes are not correctly placed or the spray arms are not rotating. Check that the dishes are placed securely. Spin the spray arms to make sure they can rotate. |

| The dishwasher does not start. | The Start/Stop start button has not been pressed for long enough. |

| The door is not properly closed. | |

| A fuse/circuit breaker has been tripped. | |

| The plug is not plugged into the wall socket. | |

| The water tap is turned off. | |

| Overflow/leaks | |

| Check that the Delayed start option has not been selected. | |

| 1 minute appears in the display | The program is taking longer than estimated. None, next time the program is run the corrected time will be displayed. |

| Water remains in the dishwasher | Blocked drainage hose. |

| Kink in drainage hose. | |

| The filters are blocked. | |

| The filter is not locked in completely. | |

| Debris in the drainage pump. | |

| Bad odour in dishwasher. | Dirt around the seals and in corners. |

| Low temperature programs have been selected for a prolonged period. | |

| The dishes are not dry enough. | Drying power too low. |

| The dishwasher is not fully loaded. | |

| Rinse aid needs topping up or dosage is set too low. | |

| Cannot close door. | The baskets are not correctly positioned. |

| The touch buttons do not react when pressed. | Dirt on the touch buttons. |

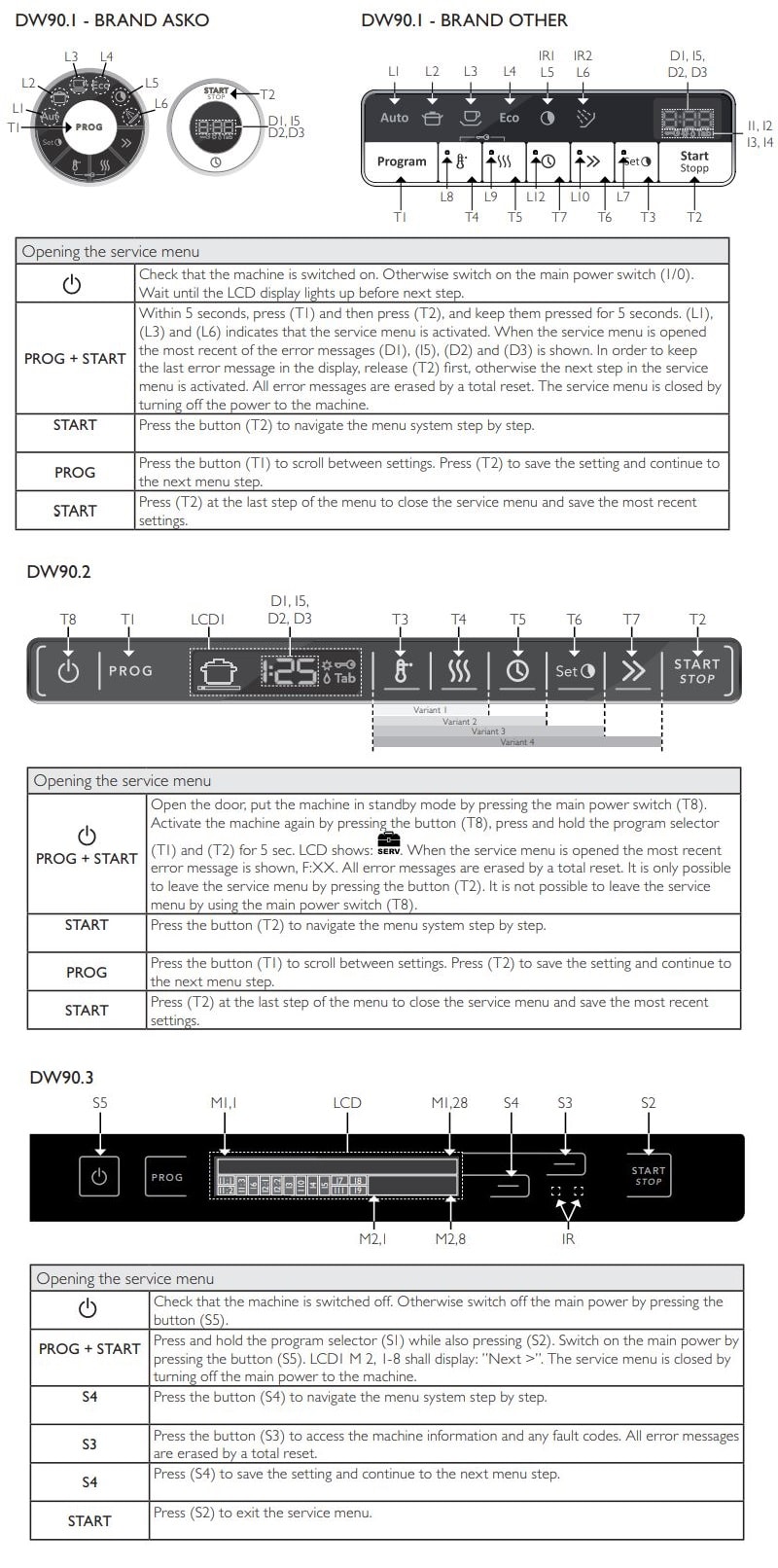

Control Panel Buttons Meaning

Manuals Pdf

Asko Dishwasher DBI664 XXLS Use and Care Manual

ASKO Dishwasher Operating Instructions D5526XLFI

Latest posts by Dylan Joseph (see all)

- Philips Coffee Maker Error Codes List and Solutions - April 10, 2024

- [Fixed] Miele Refrigerator Error Codes List - April 10, 2024

- Power Air Fryer Error Codes – Here Is How To Fix - April 8, 2024

I have an S:03 error code on my display screen after the power went off/on . I cannot understand what is the next step to remedy this.

I have the same problem, only S:05 then S:01 error codes after a power outage. Did you find a way to fix it?

I have S:03 error code. Any idea how to fix.