Smeg washing machine error codes serve as a vital reference for users. They aid in monitoring machine performance and diagnosing issues efficiently. These codes empower users to understand and potentially resolve problems independently, before resorting to technical support. By providing users with the means to troubleshoot effectively, Smeg washing machine error codes contribute significantly to the efficient use of these appliances.

Most Common Codes

| Error Codes | Solutions |

|---|---|

| OPEN | Door not properly closed. Try reclosing. |

| E1 | Aqua stop device tripped. Cut off power supply, turn off water tap and contact nearest service centre. |

| E2 | Anti-spilling device (only outside washing program) |

| E4 | NTC water in short circuit or interrupted. |

| E5 | Water not taken in for washing. See point 2 in troubleshooting table. |

| E6 | Water not pumped out. See point 4 in troubleshooting table. |

| E10 | Motor over current. |

| E11 | Motor control triac in short circuit or interrupted. |

| E12 | Tachometer. |

| E13 | PTC door block. |

| E14 | NTC dryer in short circuit or interrupted.. |

| Failure 2 | Washing program does not start. FAILURE 2. Door is not properly closed. Push it towards the machine. |

| Failure 3 | Water does not enter the machine. FAILURE 3. Disturbed water inlet. Check if: the water faucet is open, inlet pipe net filter is clean. (Push the START button again). |

| Failure 7 | Water is poorly pumped out or not at all (machine signals FAILURE 7). Water outlet is clogged. Check if: the filter is clean, outlet pipe is not jammed, outlet pipe is positioned higher than 1 m. (Push START knob again). |

| AF:01 | Water not heated within time allowed. Cycle in progress, heating phases. |

| AF:02 | The temperature difference between the two probes, “TL1” and “TC”, is more than 2°C (only active on WD series) |

| AF:04 | Probe “TL1” (chamber temperature ) shows a reading higher than the actual temperature. |

| AF:05 | Working temperature probe “TL1” is generating an abnormal signal (probe “open”). |

| AF:07 | Drying temperature probe TA1 is generating an abnormal signal (probe “open”). |

| AF:10 | Control temperature probe TCL is generating an abnormal signal (probe “open”). (only active on WD series) |

| AF:11 | No cold water during filling. |

| AF:13 | No demineralis ed water. |

| AF:17 | Cold water filling time not correct. |

| AF:19 | Demi filling time too long. The device is taking too long to take in demineralis ed water. |

| AF:23 | Not enough water. Chamber water level too low. |

| AF:25 | Malfunction related to washing pump “ML”. Washing pump pressure too low. |

| AF:26 | Malfunction involving water being taken into chamber at wrong time. Cold water intake valve “EVF” may have failed. |

| AF:28 | Malfunction involving demineralis ed water being taken into tank at wrong time. Cold water intake valve “EVF” may have failed. |

| AF:29 | Chamber does not empty. Pump-out not occurring. |

| AF:30 | During the working cycle, the chamber water level exceeds the safety level. Water safety level. |

| AF:32 | Water standing in washing chamber with device in standby. |

| AF:33 | Steam condenser water intake anomaly. No water in steam condenser. |

| AF:34 | Steam condenser water drainage failure. |

| AF:37 | Drainage problems when using a mixture of water. |

| A:41 | P1 detergent intake anomaly |

| A:42 | P2 detergent intake anomaly |

| A:43 | P3 detergent intake anomaly. Equivalent to A 41 but for P3. |

| AF:54 | Door opening detected with cycle in progress. Door interlock microswitch malfunction. |

| AF:56 | Door interlock device malfunction, automatic opening failure. |

| AF:58 | Dryer heating failure. |

| AF:67 | Dryer motor “cooling” malfunction. Cooling is included at the end of the drying phase to bring the load processed and the heating elements to a safe temperature |

| A:68 | P1 jerry can empty |

| A:69 | P2 jerry can empty |

| A:70 | P3 jerry can empty |

| AF:73 | Internal memory data storage error |

| AF:74 | Water leak from chamber. Alarm only enabled with the Acquastop accessory fitted. |

| AF:75 | No salt in softener. This alarm does not appear on the Display but is recorded in the appliance memory; the relative LED illuminates on the display. |

| AF:77 | Intake water temperature over 45°C; prewash temperature must be below 45°C. Alarm generally disabled on GW series products. |

| AF:78 | Restore fail. Motherboar d problem. Status reset error. Date not saved correctly the last time the device was switched off. |

| AF:79 | Program not compatible. Check performed at start-up: program setting error. The program cannot be run (e.g. because recycled water or an alternative drain is not available) |

| AF:84 | Dryer temperature reading higher than actual temperature |

| AF:91 | Internal memory full. No response. If the setup overwrite function is not set as on, the device shuts out; it does not perform any further cycles until the memory is cleared. Download and clear the memory following the procedure described in the WD-TRACE manual. |

| AF:92 | Drying filter maintenance. Replace the drying absolute filter and reset the counter. Also decide whether to replace the relative filter. |

| AF:93 | Device maintenance. Service the device and inspect all parts potentially subject to wear. Decide whether to make any replacements. |

| AF:94 | Temperatur e below target temperature during extension phase. T not stable. |

| AF:96 | Analog pressure switch malfunction. |

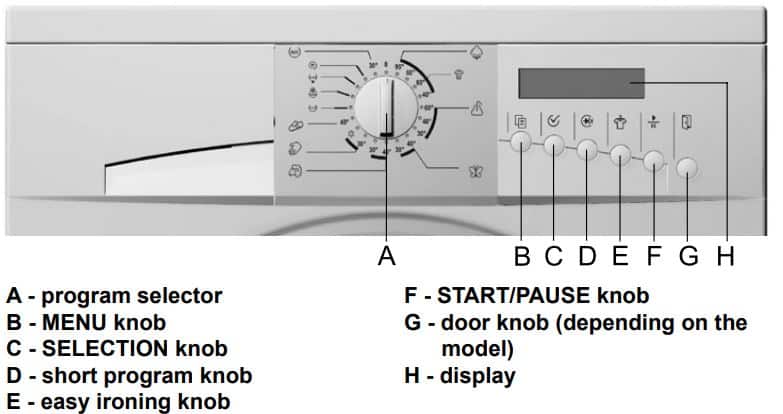

Control Panel

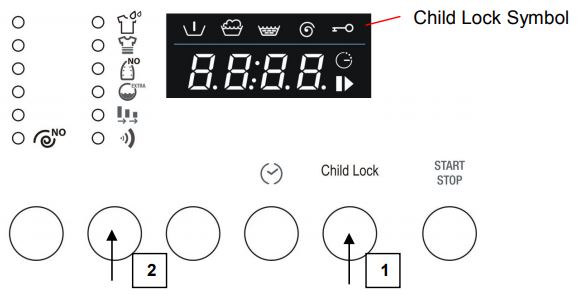

Child Protection

Operation of the washer may be protected against accidental changes of programs or functions. The function is activated by pressing the START/PAUSE button (F). Temporary disengagement of the function (during the operation):

- Keep the MENU knob (B) pressed for 4 seconds, relevant symbol flashes on the display.

- Stop the program by pressing the START/PAUSE knob (F).

- Change settings.

- Press the START/PAUSE button (F) and reactivate the child lock.

In case you fail press any knob within 15 seconds, the protection is automatically reactivated.

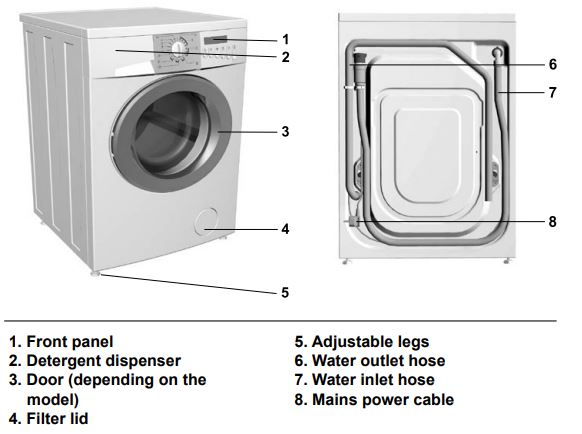

Cleaning The Water Intake Filters

The machine is fitted with a filter which protects the water intake valves. The filter is in the fitting on the intake hose which is connected to the tap The filter must be cleaned if the washing machine is not taking in water or the amount of water is insufficient.

To clean, proceed as follows:

- Remove the mains plug to disconnect the appliance from the electricity supply.

- Turn off the water tap.

- Unscrew the intake hose fitting from the tap.

- Unscrew the intake hose fitting from the tap.

- Clean the filter with water, with the aid of a small brush.

- When screwing the intake hose fitting back into place, check that the filter is positioned correctly.

Troubleshooting

This produce complies with the relevant regulations governing the safety of electrical equipment. For safety reasons, any technical inspections or repairs must be performed by qualified staff, to prevent all hazards for the user. If the appliance does not work, before calling the After-Sales Service, to avoid unnecessary expense, check yourself that the operations listed in this troubleshooting table have been carried out.

| Trouble | Possible Cause-Remedy |

|---|---|

| The machine does not work (display is not illuminated). | Machine is not powered. Check if: plug is in the socket, there is power in the socket, the fuse is OK. |

| Water does not enter the machine. | Filter is not tightly screwed in. Inlet pipe is not tightly screwed to the machine or to the water faucet. Outlet pipe fell to the floor. Tighten the filter properly. Tighten the inlet pipe. Affix the outlet pipe to the drain. |

| The machine moves during operation. | The machine is not properly leveled. Transport brackets are not removed. Level the machine with the adjustable legs. Remove transport brackets. |

| The machine vibrates during the spin. | Unevenly distributed laundry, especially with very small quantities (for ex. only the bathrobe). This is normal, the machine will reduce the RPM if vibrations are too strong. Wash larger quantity of laundry. |

| Excessive foaming during washing. | Excessive measure of detergent. Use washing powder according to the instructions by the producer and according to the water hardness and soiled laundry. Use only detergents for machine washing. |

| Laundry is not properly spun. No failure is reported. | The machine switched on the UKS* function. Because of bad laundry balance, the machine has automatically reduced spin RPM. The machine operates normally. Wash large and small pieces of laundry together. |

| Greasy wads appear on the laundry. | Too little detergent (laundry was very greasy). Wash the laundry again. Add more detergent for such soiled laundry, or use liquid detergent. |

| Laundry is stained after washing. | You used liquid detergent or detergent for colored laundry which does not contain whitener. You selected inappropriate program. Use the detergent containing whitener. Select the heavily soiled laundry program, or activate soaking function. |

| White powdery residues on the laundry. | It is not the consequence of bad rinsing, but because of neo-phosphate detergents containing non soluble components (zeolites) for water softening. Such substances may be deposited upon the laundry. Inappropriately selected program. Immediately rinse the laundry once again. Use liquid detergents which do not contain zeolites. Try removing the residues with the brush. Use program for heavily soiled laundry, or activate soaking function. |

| Detergent residues in the dispenser. | Low water flow pressure. Some detergents may stick to the dispenser rather hard if it is wet. Clean the inlet pipe screen. Wipe the dispenser prior loading detergent. |

| Softener is not completely rinsed, or water is left in the dispenser dish. | Sucking cover is not correctly positioned or is clogged. Clean the dispenser and firmly fix the cover to its place. |

| Washing time is longer than usual. | The machine switched on the UKS* system because of uneven laundry load. Power failure occurred. Clean water sensor is engaged. Washing program time may be prolonged for 10 minutes and the machine still functions perfectly. Time is prolonged for the power failure period. Time is prolonged for extra rinses. |