Ferroli boiler error codes help identify issues with the device. These codes assist in quickly and accurately diagnosing problems, ensuring the smooth operation of the boiler unit.

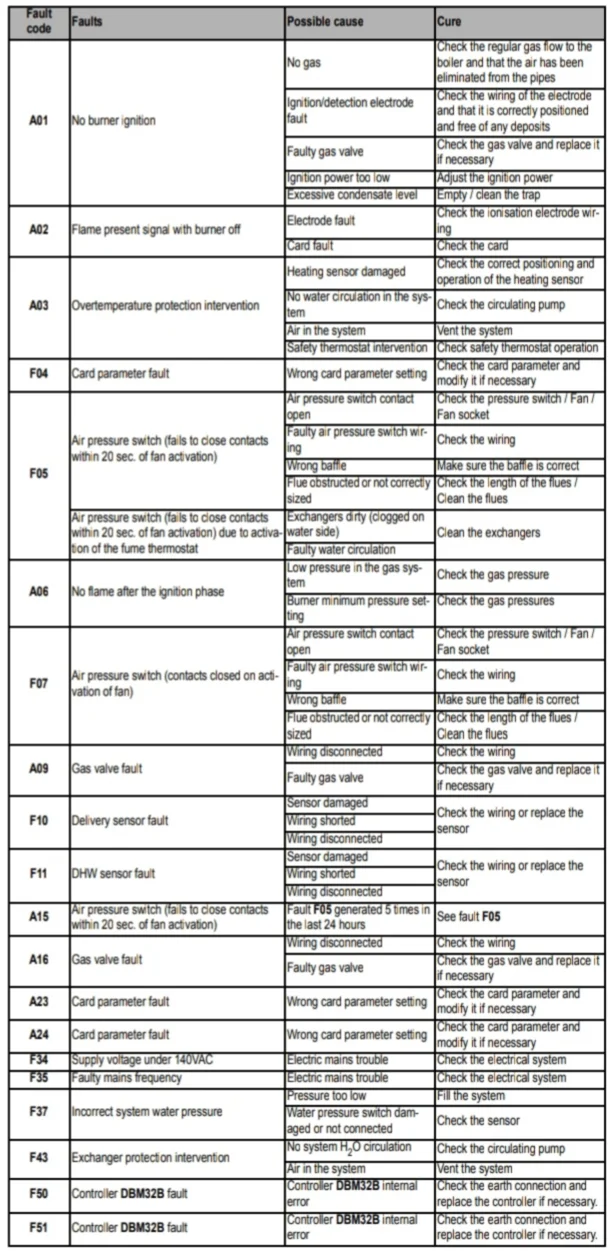

Fault Codes List

The boiler is equipped with an advanced self-diagnosis system. In case of a boiler fault, the display will flash together with the fault symbol indicating the fault code.

There are faults that cause permanent shutdown : to restore operation, press the RESET button for 1 second or RESET on the optional remote timer con- trol if installed; if the boiler fails to start, it is necessary to eliminate the fault.

Faults marked with the letter “F” cause temporary shutdowns that are automatically reset as soon as the value returns within the boiler’s normal working range.

| Fault Codes | Problem |

|---|---|

| A01 | No burner ignition. |

| A02 | Flame present signal with burner off |

| A03 | Overtemperature protection activation |

| A04 | Fume extraction duct safety device activation |

| A05 | Fan protection activated |

| A06 | No flame after ignition stage (6 times in 4 minutes) |

| F07 | High fume temperature |

| F10 | Delivery sensor 1 fault. heck the wiring or replace the sensor. |

| F11 | Return sensor fault |

| F12 | DHW sensor fault |

| F13 | Fume sensor fault |

| F14 | Delivery sensor 2 fault |

| F15 | Fan fault |

| F20 | Incorrect system water pressure |

| F21 | Incorrect system water pressure |

| A26 | System protection activation |

| F34 | Supply voltage under 170V |

| F35 | Faulty mains frequency |

| F37 | Incorrect system water pressure |

| F39 | External probe fault |

| F40 | Incorrect system water pressure |

| A41 | Sensor positioning |

| F42 | Heating sensor fault |

| F47 | System water pressure sensor fault |

i25-i29 Model Codes

Part Meaning

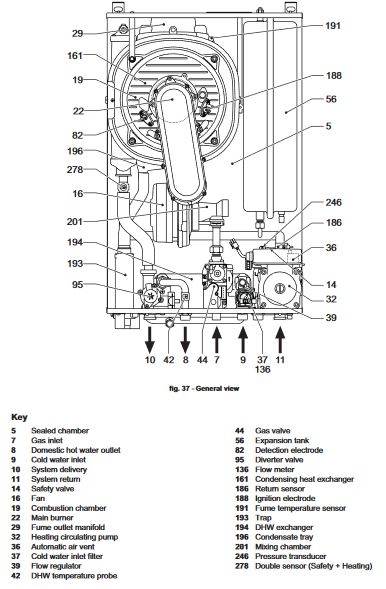

Periodical Check

To keep the unit working properly over time, it is necessary to have qualified personnel make an annual check that in-cludes the following tests:

- The control and safety devices (gas valve, flow meter, thermostats, etc.) must function correctly.

- The fume extraction circuit must be fully efficient.

- The airtight chamber must be sealed

- The air-fume end piece and ducts must be free of obstructions and leaks

- The condensate evacuation system must be efficient with no leakage or obstructions.

- The burner and exchanger must be clean and free of scale. When cleaning, do not use chemical products or wirebrushes.

- The electrode must be free of scale and properly positioned.

- The gas and water systems must be airtight.

- The water pressure in the cold water system must be about 1 bar; otherwise, bring it to that value.

- The circulation pump must not be blocked.

- The expansion tank must be filled.

- The gas flow and pressure must correspond to that given in the respective tables.

The boiler casing, panel and aesthetic parts can be cleaned with a soft damp cloth, possibly soaked in soapywater. Do not use any abrasive detergents and solvents.

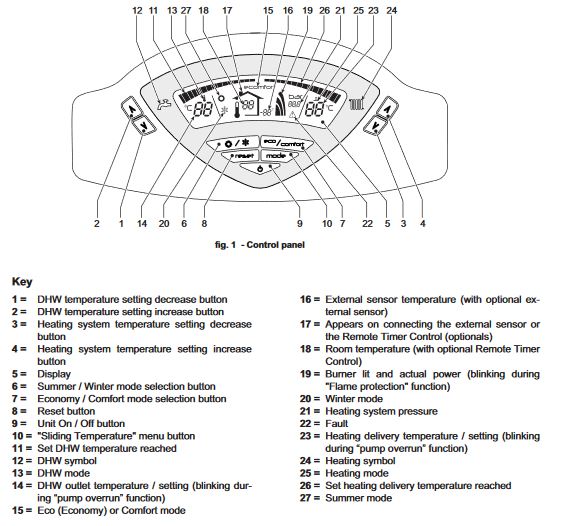

Control Panel