Hotpoint established in 1911 is a British domestic appliances brand that has been around for more than 100 years. The brand’s ownership is divided between the American brand Whirlpool which has rights in Europe and the Chinese brand Haier which has rights in the Americas. All of this was made possible after the purchase of GB Appliances back in 2016.

Since its inception the company has been working on a wide range of appliances, starting with the electric iron in 1912, and electric cookers in 1919. Over the years the company kept offering new and improved versions of home appliances and now offers a complete range that is designed keeping your ease of use in mind. However, the company is known for its attention to detail when it comes to safety hazards and offers the best choices available.

Hotpoint might be a high-ranking company, but from time to time customers have complained about system errors. Fortunately, most of these errors can be fixed on your own. So rather than ignoring the error codes, your appliance is showing its time to note down the Hotpoint dishwasher error code and get to the bottom of the problem. To help you out we have listed down the most common error codes of Hotpoint dishwashers.

Most Common Codes

| Fault Codes | Solution |

|---|---|

| F01 | Anti-Flooding Overflow. Bowl ƀoat microswitch electrical circuit OPEN! (must be closed). |

| F02 | Water Fill Solenoid Valve Failure. Fill valve admits water even when deactivated. |

| F03 | Drain Timeout. Maximum drain time elapsed. |

| F04 | Thermistor (NTC) not compliant. Thermistor (NTC) circuit not compliant (break in continuity or short-circuit) |

| F05 | Pressure Switch Non Compliant. Pressure switch has not indicated completion of fill, even though turbine has filled appliance with water correctly. |

| F06 | Water Fill Timeout. Maximum interval of time for completion of fill has been exceeded. |

| F07 | Water Turbine Damaged. Turbine has given no signal indicating entry of water, even though fill has effectively been completed. |

| F08 | Temperature Timeout (1 Hour). Maximum interval of time for establishing temperature has been exceeded (1 hour). |

| F09 | Software recognition error. Main board not programmed. Software recognition error Processor not programmed. |

| F10 | Heating Element Circuit Not Compliant. Heating Element Circuit Not Compliant (Circuit Open). |

| F11 | Not Applicable to this model. Note: This code may display during an Auto Test. |

| F12 | Communication error between main board and display. No communication/connection between main board and user interface. |

| F13 | Main Board Not Working. Main Board Not Working. |

| F15 | Virtual Sensor. Reading between Wash pump and Drain pump not consistent. |

Fault Codes and Diagnostics

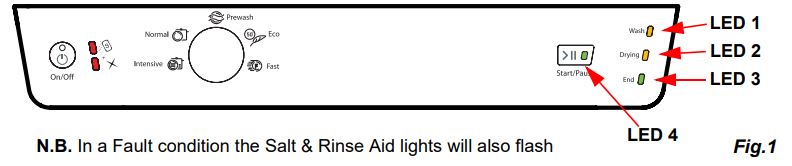

If an error is detected in programme, the programme will be terminated and one of the following errors will be displayed using a combination of the programme LED’s on the console panel. The relevant LED(s) will flash in the event of a fault. The On/Off LED will also flash.

Fig. 1 identifies the programme progress LED to the corresponding LED shown in the fault code chart.

| LED | Fault and Possible Cause |

|---|---|

| 1 | Overflow (water in base pan). Leak from water line. |

| 2 | Valve or Turbine faulty or disconnected. Inlet valve, connections, valve letting water pass through when off. |

| 3 | Thermistor circuit. Thermistor / module. |

| 4 | Time out heating. Heater Open circuit or NTC thermistor detached from casing. |

| 1 + 2 | Time out draining. Pump connections, blockage, module, circulation pump. |

| 2 + 3 | Time out filling. Customer's tap, Inlet valve, connections, timer, water turbine. |

| 1 + 3 | Pressure Switch. Mesh plate, filter or microfilter, pressure switch, circulation pump. |

| 1 + 4 | Software recognition error. Module not programmed, wrong keypad. |

| 2 + 4 | Heating circuit. Heating element, connections, module, relay, pressure switch. |

| 3 + 4 | Communication Error |

| 1 + 3 + 4 | Non-operative module |

| 1 + 2 + 3 | Turbine faulty. Module has detected no Turbine rotation. check turbine and wiring. |

Resetting after a fault: This is achieved by switching OFF the dishwasher with the On/Off switch and waiting 30 seconds. The dishwasher is then ready for use.

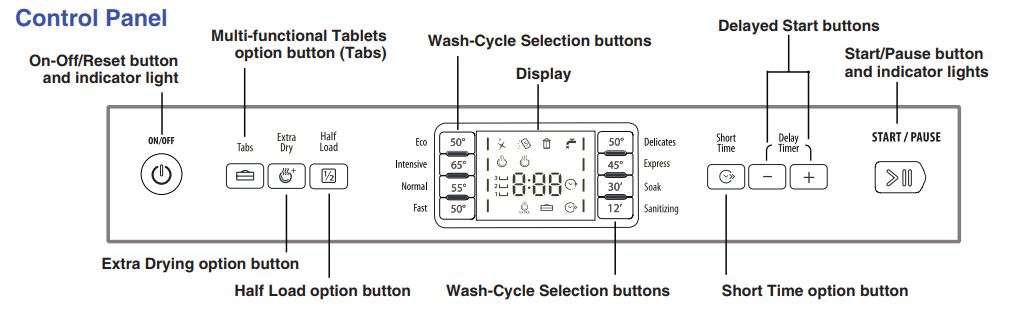

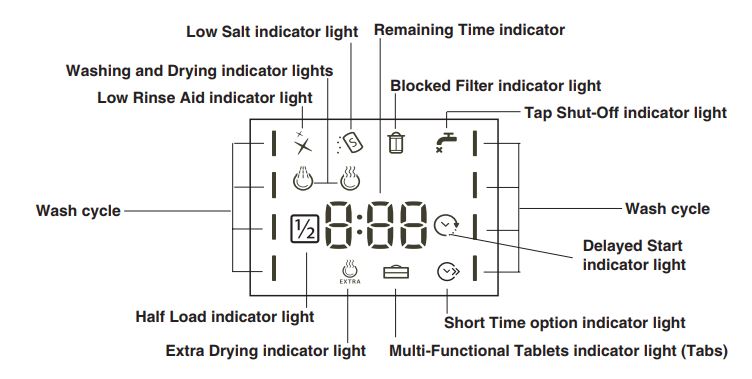

Control Panel

Fully Integrated Dishwasher with Display and O3 Active Oxygen

| Flashing Number | Fault and Possible Cause |

|---|---|

| 1 | Overflow (water in base pan). Leak from water line. |

| 2 | Valve or Turbine faulty or disconnected. Inlet valve, connections, valve letting by when off. |

| 3 | Time out draining. Pump connections, blockage, module, circulation pump. |

| 4 | Thermistor circuit. Thermistor / module. |

| 6 | Time out filling. Customer's tap, Inlet valve, connections, timer, water turbine. |

| 7 | Turbine faulty. Module has detected no Turbine rotation. check turbine and wiring. |

| 8 | Heater Open circuit or NTC thermistor detached from casing. |

| 9 | Software recognition error. Module not programmed, wrong keypad. |

| 10 | Heating circuit. Heating element, connections, module, relay, pressure switch. |

| 11 | Wash Pump Faulty. Wash Pump faulty, or wiring/connections between pump motor and module faulty. |

| 12 | Communication Error |

| 13 | Non-operative module |

| 15 | Virtual Sensor |

Troubleshooting

Whenever the appliance fails to work, check for a solution from the following list before calling for Assistance.

Problem: The dishwasher does not start or cannot be controlled.

Possible causes / Solutions:

- Switch off the appliance by pressing the ON/OFF button, switch it back on after approximately one minute and reset the program.

- The appliance has not been plugged in properly.

- The dishwasher door has not been shut properly.

Problem: The door won’t close.

Possible causes / Solutions: The lock was released. Strongly push the door until a “clacking” noise is heard.

Problem: No water drains out from the dishwasher.

Possible causes / Solutions:

- The dishwasher cycle has not yet finished.

- The water inlet hose is bent (see Installation).

- The drain duct is blocked.

- The filter is clogged up with food residues.

Problem: The dishwasher makes excessive noise.

Possible causes / Solutions:

- The dishes are rattling against each other or against the sprayer arms.

- Excessive foam presence: the detergent has not been measured out correctly or it is not suitable for use in dishwashers.

Problem: The dishes and glasses are covered in a white film or limescale deposits.

Possible causes / Solutions:

- The level of the refined salt is low or the dosage setting is not suited to the hardness of the water (see Rinse aid and salt).

- The lid on the salt dispenser is not closed properly.

- The rinse aid has been used up or the dosage is too low.

Problem: The dishes and glasses are streaked or have a bluish tinge.

Possible causes / Solutions: The rinse aid dosage is too high.

Problem: The crockery has not been dried properly.

Possible causes / Solutions:

- A wash cycle without a drying programme has been selected.

- The rinse aid has been used up or the dosage is too low (see Rinse aid and salt).

- The rinse aid dispenser setting is not high enough.

- The crockery is made from non-stick material or plastic.

Problem: The dishes are not clean.

Possible causes / Solutions:

- The racks are overloaded.

- The crockery has not been arranged well.

- The sprayer arms cannot move freely.

- The wash cycle is too gentle.

- Excessive foam presence: the detergent has not been measured out correctly or it is not suitable for use in dishwashers.

- The lid on the rinse aid compartment has not been shut correctly.

- The filter is dirty or blocked.

- The refined salt level is low.

Cleaning the filters

The filter assembly consists of three filters which remove food residues from the washing water and then recirculate the water. They should be cleaned if you wish to achieve the best results in every wash.

Clean the filters regularly. The dishwasher should not be used without filters or if the filter is loose.

After several washes, check the filter assembly and if necessary clean it thoroughly under running water, using a non-metallic brush and following the instructions below:

- Turn the cylindrical filter C in an anti-clockwise direction and pull it out (fig. 1)

- Remove the cup filter B by exerting a slight pressure on the side flaps (fig. 2);

- Slide out the stainless-steel plate filter A. (fig. 3)

- Inspect the trap and remove any food residues. NEVER REMOVE the wash-cycle pump protection (black detail) (fig.4)

After cleaning the filters, re-place the filter assembly and fix it in position correctly; this is essential for maintaining the efficient operation of the dishwasher.