Indesit is an all-Italian company that offers domestic appliances all over Europe. What was once the leading manufacturer and distributor in Europe, are still listed as a top choice. While the competition has risen since 1975, they have managed to maintain their hold over major European markets such as the UK, Poland and Italy. Employing over 16 ‘000 people that are spread across Europe.

Offering customers a wide range of fridges, freezers, washing machines, dryers, dishwashers, hoods, ovens, cookers, and hobs to choose from. So you can create a fully functional kitchen that works best based on your unique requirements. All the while making sure you enjoy durable and reliable appliances.

Indesit washing machines are considered to be one of the best, but that does not mean they are free from issues and errors. There might come a time when you find an error code displaying on the screen, so rather than worrying, we suggest you note it down and match it using the Indesit washing machine error codes below.

Most Common Codes

| Error Codes | Problem |

|---|---|

| F01 | Motor triac |

| F02 | Motor, jammed/ tacho |

| F03 | NTC fault |

| F04 | Pressure switch stuck on empty |

| F05 | Pressure switch stuck on full |

| F06 | N/A? |

| F07 | Heater relay |

| F08 | Heater relay |

| F09 | EPROM/setup error |

| F10 | Pressure switch not sensing |

| F11 | Pump/draining error |

| F12 | Communication error |

| F13 | Dryer ntc/ fan motor |

| F14 | Dryer heater |

| F15 | Dryer heater relay |

| F16 | N/A? |

| F17 | Door lock |

| F18 | Communication error (3 phase motor) power board |

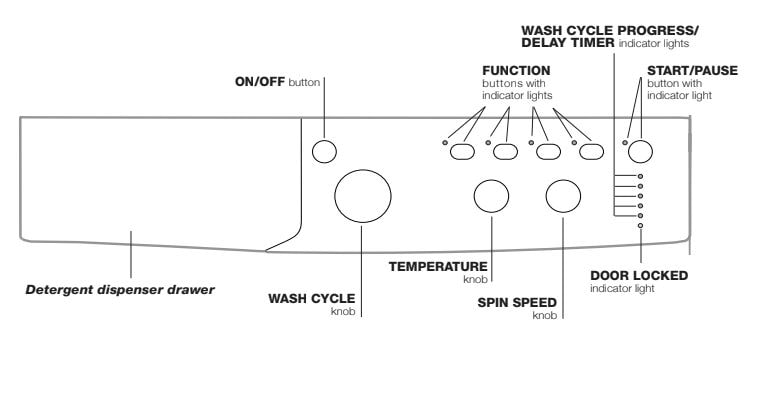

Control Panel

Cleaning the pump: The washing machine is fitted with a selfcleaning pump which does not require any maintenance. Sometimes, small items (such as coins or buttons) may fall into the protective pre-chamber at the base of the pump. To access the pre-chamber:

- Take off the cover panel on the front of the machine by first pressing it in the centre and then pushing downwards on both sides until you can remove it

- Unscrew the lid by rotating it anticlockwise (see figure): a little water may trickle out. This is perfectly normal

- 3.Clean the inside thoroughly

- Screw the lid back on

- Reposition the panel, making sure the hooks are securely in place before you push it onto the appliance.

Troubleshooting

Your washing machine could fail to work. Before contacting the Technical Assistance Centre (see “Assistance”), make sure that the problem cannot be solved easily using the following list.

| Problem | Possible causes / Solutions |

|---|---|

| The machine does not switch on | The appliance is not plugged into the socket fully, or not enough to make contact. |

| There is no power to the socket, or the fuse has blown in the mains plug. | |

| The wash cycle does not start | The door is not closed properly. |

| The ON/OFF button has not been pressed. | |

| The START/PAUSE button has not been pressed. | |

| The water tap has not been turned on to allow water to flow into the machine. | |

| A delayed start has been set. | |

| The machine does not fill with water or the indicator light for the first wash cycle stage flashes rapidly | The water inlet hose is kinked. |

| The water inlet hose is not connected to the water supply. | |

| The water pressure is too low. | |

| The water tap has not been turned on to allow water to flow into the machine. | |

| There is no water supply to the house. | |

| The inlet valve filter is blocked. | |

| The START/PAUSE button has not been pressed. | |

| The machine continuously fills with water and continually drains away or Water left in the drum or Stuck on wash | The top of the drain hose is too low - It must be fitted at a height between 65 and 100 cm from the floor. |

| The drain hose is connected incorrectly to the sink trap allowing water to run into the machine, the drain hose must be positioned higher than the bottom of the sink to prevent water flowing down the drain hose. | |

| The end of the drain hose has been pushed too far down the standpipe, the ‘U’ bracket should be fitted 100 mm from the end of the drain hose. | |

| The machine does not drain or spin | The Pump filter is blocked. |

| The drain hose is kinked. | |

| New Installation - The blanking cap or spigot has not been removed if connected under a sink. | |

| The drain hose or sink trap is blocked. | |

| The wash cycle does not include draining, some wash cycles require the drain phase to be started manually. | |

| The programme takes too long | Programme times will vary due to water pressure, the incoming water temperature and if the wash load goes out of balance. This will increase the programme times accordingly. |

| The machine vibrates a lot during the spin cycle | The feet have not been adjusted, enabling the machine to rock. |

| New Installation - Either the Transit Bolts including the plastic spacers, or the Polystyrene Packaging have not been removed when installing the machine. | |

| The machine is trapped between cabinets and/or walls. | |

| The load is in a slight out of balance condition and machine is spinning, but at a lower speed. | |

| The machine is noisy. | There will always be some motor, pump and drum noise during spin. |

| The machine wont spin properly | Out of Balance detected when attempting to go into a spin cycle - If this happens the machine will continue to try to repeat the distribution of the load required before the machine will go into higher spin speeds - This will increase the programme time accordingly. This is a safety feature to prevent damage. Out of Balance can be caused by washing a single heavy item (eg duvet, quilt, etc). - Try the programme again using a different load. |

| The machine leaks from the dispenser | The dispenser drawer is blocked with detergent and requires cleaning. |

| The water pressure is too high and requires turning down - turn down the tap on the water supply pipe slightly and try again. | |

| The machine is tilting forwards - It must be level when in its final position. | |

| The machine leaks (other than dispenser) | The fill hose is loose, check both the cabinet and tap ends. |

| The fill hose is tight but still leaks, if so replace the rubber washers, or the fill hose is missing the rubber washer. | |

| The drain hose is not fixed in properly. | |

| The indicator lights on the console are flashing rapidly | Switch off the machine and unplug it, wait for approximately 1 minute and then switch it back on again If the problem persists contact the Technical Assistance Service. |

| The machine smells | The machine requires a service wash. Run a 90 degree wash cycle with detergent and no laundry. |

| The machine door cannot be opened | The door will not open until the door lock indicator light goes out shortly after the program has finished. |

| Door Seal damaged at the bottom | The door seal has drainage holes at the bottom - This is normal. |

| The water level is too low when the machine is washing. | The water level is correct if it can be seen at the bottom of the door. |

| There is too much foam | The detergent is not suitable for machine washing (it should display the text ‘for washing machines’ or ‘hand and machine wash’ or the like). |

| Too much detergent was used - less detergent is required in soft water. | |

| After completing the programme, or before starting a programme, the machine has turned itself off (no lights). | To comply with new energy saving regulations the machine is fitted with an automatic standby system. Press ‘ON/OFF’ button for 3 seconds to activate the machine, it can then either be switched off or a new programme selected. |

Not emptying contents from pockets may cause pump or drain blockages, or may damage the machine. Do not wash items which do not have a wash label, or wash items that are not intended as machine washable.

Child Lock

To activate the control panel lock, press and hold the button for approximately 2 seconds. This prevents wash cycles from being modified accidentally (except for the ON/OFF button), especially if there are children in the home. To deactivate the control panel lock, press and hold the button for approximately 2 seconds.