Whirlpool washing machines help identify and diagnose problems by using error codes that indicate the type and source of the error. These error codes assist the user in understanding what went wrong and taking necessary measures.

In this article, you will discover the common error codes of Whirlpool washing machines and what they mean. Understanding the error codes, finding solutions, and knowing when to seek technical support will enable you to resolve issues quickly and effectively.

Most Common Codes

| Error Codes | Solution |

|---|---|

| FH | No water inlet |

| FA | Aqua stop failure |

| FP | Drain failure |

| F01 | Motor triac shorted. Check motor and module connections. |

| F02 | Motor jammed or tacho detached. Check motor and module connections. |

| F03 | NTC either short or open circuit. Check thermistor and module connections. |

| F04 | Pressure switched jammed empty. Check ressure switch and module. |

| F05 | NTC failure |

| F06 | Tachometer failure (no motor movement detected) |

| F07 | Triac short circuit detection (motor control module) |

| F08 | Heater fault |

| F09 | Overflow |

| F10 | Motor control unit failure |

| F11 | Communication error (control unit) |

| F12 | Electronic Control fault |

| F13 | Dispenser circuit error |

| F14 | EEPROM failure (control unit) |

| F15 | Motor control unit error |

| F16 | Control unit failure |

| F17 | Door Lock |

| F18 | Communications error |

| F20 | Control unit failure |

| F21 | Control unit failure |

| F22 | Control unit failure |

| FDL | Door lock error |

| FDU | Door unlock error |

| Sud | SUDS LOCK (Overdose of Detergent detected during the Wash Cycle) |

| F0E1 (rl) | Load detected during the washer cleaning cycle (rl = remove load). During the cleaning cycle, a load was detected inside the drum. Clear error code and run a cleaning cycle to verify problem. |

| F1E1 | CCU error. A corrupted onboard eeprom or communication error between the ccu and onboard eeprom has occurred. one of the main relays is not working properly. |

| F1E2 | MCU error - multiple resets. Motor control unit (mcu) has an internal malfunction, repeating under or over voltage, or over current conditions. can also be caused by momentary loss of neutral feed to mcu during the spin cycle. if the error occurs during a high-speed spin, the door will remain locked for 3 minutes. |

| F2E3 | Unsupported cycle. Cycle corruption, or ccu is not compatible for this specific model of washer. |

| F3E1 | Pressure switch / pressure sensor error. The ccu detects an out of range pressure signal. the use of analog pressure sensor or digital pressure switch is model dependent, but the procedure to detect this error does not change. |

| F3E2 | Temperature sensor error. This error is displayed if the water temperature sensor value is out of range (23°f to 217°f [–5°c to 103°c]). |

| F4E0 | Heater is not detected. This error is generated when the ccu cannot detect the temperature rising during step c01 of the quick diagnostic test. this error code is available only in service diagnostic |

| F5E1 | Door switch error. This code is generated if the door has not been open for 3 consecutive cycles, or the door switch is open while the door is locked for more than 5 seconds. if this occurs during normal operation, the buzzer beeps 3 times. this error code is available only in service diagnostics. |

| F5E2 | Door lock error. At the start of a cycle, the washer attempts to lock the door 6 times. if door cannot be locked, the washer goes into pause mode and a code is generated. this code is available only in service mode. |

| F5E3 | Door unlock error. At the start of a cycle, the washer attempts to unlock the door 6 times. if door cannot be unlocked, the washer goes into pause mode and a code is generated. this code is available only in service diagnostics. |

| F6E1 | Communication error between ccu and mcu. Communication between the central control unit and the mcu has not been detected. |

| F6E2 | Communication error ui to ccu. Communication between Central Control Unit (CCU) and User Interface (UI) has not been detected. |

| F6E3 | Communication error ccu to ui. Communication between central control unit (ccu) and user interface (ui) has not been detected. |

| F7E1 | Drive motor speed sensing error / washer overload. The mcu is unable to properly detect motor speed and the washer shuts down. if error occurs during high-spin, the door remains locked for 2–3 minutes. |

| F7E2 | Mcu overheat and/or motor overheat the heat sink exceeds 212°f (100°c). If this occurs, the ccu will reset the mcu and wait for the motor and/or the mcu to cool down before restarting. after 4 attempts, f7e2 is displayed. |

| F8E0 | Steam inlet valve error (not available on all models). This error is displayed when the steam valve malfunctions. this error can be seen only in service diagnostics. |

| F8E1 | No water detected entering washer or pressure switch trip not detected. The washer does not detect water input after 13 minutes of filling. |

| F8E2 | Dispenser system error. Dispenser motor is unable to reach the desired position. |

| F8E3 | Overflow condition. The overflow condition occurs if there is too much water or foam in the washer and the overflow contact on the pressure switch is closed for more than 2 minutes, 30 seconds or 5 times during the same cycle. if overflow occurs, the valves are closed and the drain pump switches on for at least 30 seconds. |

| F8E4 | Flow meter fault. If less than 0.1l of water has entered the tub after 30 seconds from the start of the quick diagnostic test, this error will be displayed. this error code is available only in service diagnostics. |

| F9E1 | Long drain. If the drain time exceeds 8 minutes without reaching reset level in pressure sensor, the valves are turned off and the drain pump will stop running. NOTE: Suds can cause delays in draining. Washer drains for 4 minutes, pauses 5 minutes, then tries again for 4 additional minutes of draining. F9E1 will display if washer does not drain. (Normal drain takes less than 2 minutes) |

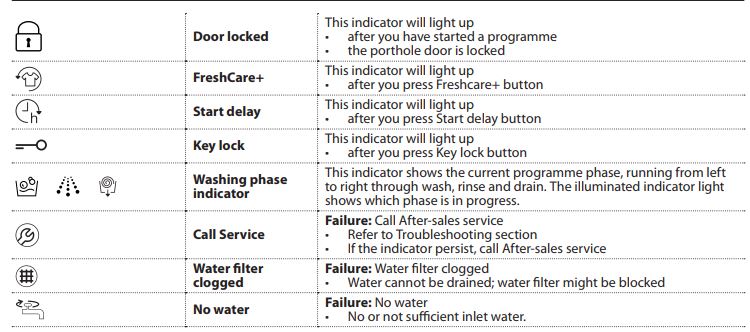

Control Panel

Troubleshooting

Your washing machine is equipped with various automatic safety and feedback functions. They enable failures and needed maintenance to be detected and indicated accordingly. These failures are frequently so minor that they can be removed within a few minutes.

Water tap closed

Possible Causes: No or not sufficient water supply because:

- Water faucet is closed.

- There are kinks in inlet hose.

- Water faucet pressure is too low.

- Mesh filters in inlet hose are clogged.

- Water inlet hose is frozen up.

Solution:

- Open the water faucet.

- Make sure there are no kinks in the inlet hose.

- Make sure water pressure is sufficient.

- Clean the mesh filters in the inlet hose.

- Install the washer at an ambient temperature of at least 41°F (5°C).

- After the problem has been corrected, touch the START/

- PAUSE button. If the problem persists, touch and hold the

- POWER button for at least 3 seconds.

Clean filter

Possible Causes: Waste water is not pumped out because:

- There are kinks in drain hose.

- Drain hose is blocked or frozen up.

- Filter is blocked.

- Pump is blocked.

Solution:

Check the drain hose for kinks. Install the washer at an ambient temperature of at least 41°F (5°C). Clean the drain pump filter as described in the “Cleaning the Drain Pump Filter/Draining Residual Water” section. After the problem has been corrected, touch the START/ PAUSE button. If the problem persists, touch and hold the POWER button for at least 3 seconds

Door open indicator blinks

Possible Causes: The door cannot lock

Solution: Firmly press the door in the area of the door lock to properly close it. Then touch the START/PAUSE button. If the problem persists, touch and hold the POWER button for at least 3 seconds

FdL (or F29)

Possible Causes: The door cannot unlock

Solution: Firmly press the door in the area of the door lock. Then touch and hold the POWER button for at least 3 seconds. If the Hot cycle is selected, wait until cool down and touch and hold the POWER button again for at least 3 seconds. Turn on the washer. If the failure still appears, check and eventually correct the possible cause as indicated for the “Clean filter” error code. Then turn on the washer again. If the door does not unlock, touch and hold the POWER button for at least 3 seconds. If the door still does not unlock, refer to the “How to Open Door in Case of Failure” section. Before draining water/ opening the door, wait until the water has cooled down (for hot wash programs).

Fod

Possible Causes: Excessive foam formation (maybe by overdosage of detergent) interrupted the program/cycle. This interruption may be repeated several times until foam is adequately reduced.

Solution: Start the Rinse & Spin program, with the Intensive Rinse option. Follow the detergent manufacturer’s dosing recommendations. Use the Dosing Aid option. Make sure the drain pump filter is clean

F20 or F60

Possible Causes: Failure of an electronic component

Solution: Turn off and unplug the washer. Close the water faucet. See the “Assistance or Service” section to contact a service representative

F24 (service)

Possible Causes: Too much laundry for a program/cycle with a small maximum load

Solution: Select and start the Rinse & Spin program to complete the interrupted wash program/cycle. Do not overload the washer. Follow the maximum load size indicated in the “Program/ Cycle Guide” section

F24 (service)

Possible Causes: Too much inlet water

Solution: Turn off the water faucet. Touch and hold the POWER button for at least 3 seconds to drain the water; wait until the drain phase has ended (“End” will appear on the display). Turn on the water faucet again. If water immediately flows into the washer without a program/cycle being started, an electrical component has failed. Close the water faucet, turn off and unplug the washer. See the “Assistance or Service” section to contact a service representative

All other F.. failures

Possible Causes: Failure of an electrical component

Solution: Touch and hold the POWER button for at least 3 seconds to reset the control. If the problem persists, turn off and unplug the washer. Close the water faucet. See the “Assistance or Service” section to contact a service representative

Gurgling or Humming

Possible Causes: Washer may be draining water

Solution: The pump may make a humming sound with periodic gurgling or surging as final amounts of water are removed during the spin/drain cycles. This is normal at certain stages of the cycle

Rolling or sloshing and occasional clicking (on low-speed spin)

Possible Causes: Steel balls in the balancing system are balancing the load

Solution: This is normal at certain stages of the cycle

Load not completely covered in water

Possible Causes: Water level not visible on door or does not cover clothes

Solution: This is normal for an HE front-load washer. The washer senses load sizes and adds the correct amount of water for optimal cleaning

Spin speed “0” blinks on the control panel and/or laundry is still very wet

Possible Causes: An unbalanced load prevented the Spin cycle to avoid damage to the washer

Solution: To spin wet laundry, add more laundry items of different sizes and start the Rinse & Spin program. Avoid small laundry loads consisting of a few large, absorbent items and wash different-sized items in one load

Desired setting or option does not light

Possible Causes: For best performance, not all settings are available with each cycle, and some options cannot be used together

Solution: See the “Program/Cycle Guide” for the available settings and options for each cycle

Detergent dispenser contains detergent residue after program ends

Possible Causes: Inlet water pressure is too low; the mesh filter of the water supply hose may be blocked

Solution: Make sure the water faucet is properly opened. Check the mesh filters of the inlet hose and clean if necessary

Single-dose laundry packet not dissolving

Possible Causes: Adding laundry packet incorrectly

Solution: Be sure laundry packet is added to washer drum before adding clothes. Do not add packet to dispenser. Follow the manufacturer’s instructions to avoid damage to your garments

Liquid detergent on door glass prior to beginning of cycle

Possible Causes: Detergent is free to flow from the single-dose dispenser

Solution: Do not add liquid detergent until laundry is loaded

Manual

Whirlpool Washing Machine Manual PDF

Whirlpool Washing Machine User Manual PDF

Reference: www.whirlpool.com