Electrolux AB is a multinational home appliance manufacturer based in Sweden. A collaboration between Lux AB and Svenska Elektron AB, the company became Electrolux AB. Initially, the company only sold vacuum cleaners in Europe, and soon started shifting towards other home appliances. Starting with an absorption refrigerator, followed by washing machines, dishwashers, and food service equipment.

Ranked as the world’s second latest appliance maker (based on units sold) it comes just after Whirlpool. While Electrolux sells its items with its own brand names, there are brands it uses to sell its appliances. Today, Electrolux washers are considered to be one of the best choices, making them an easy pick for your residential use. These come in a range of models to choose from, each one offering a different capacity and features.

Fully automatic washers come with LCD panels that are designed to help you operate your system with ease. However, it can all come crashing down when you see an error on the screen. Rather than panicking, we suggest you note it down and find out the issue causing an error. To help you out we have listed down some of the most common error codes for Electrolux Washers.

Codes Table

| Error Codes | Problem |

|---|---|

| 01 | NO WATER. Water level has not reached set level within time set. After this error message appears and the machine is reset, the machine will try again. |

| 02 | DOOR OPEN. Signal from microswitch which checks door status absent during program. After this error message appears and the machine is reset, the machine will try again. |

| 03 | DOOR UNLOCKED. Signal from microswitch which detects when the door is locked absent during program. |

| 04 | NTC LOW TEMP. The temperature is below the lowest value allowed (open circuit in temperature sensor). |

| 05 | NTC HIGH TEMP. The temperature is above the highest value allowed (short-circuit in temperature sensor). |

| 06 | WATER IN DRUM. The water level is higher that the level EMPTY at the start of the program. |

| 07 | MACHINE OVER-FILLED. The water level is higher than the ”LEVEL OVERFILL” (i.e. DRUM OVER-FILLED) level. If this function is switched off (=N), instead the drain valve will open for a short time and discharge some of the water. This is described under the function ”DRAIN TIME WHEN OVERFILL” (i.e. DRAIN TIME AFTER OVER-FILLING) earlier in this section. |

| 08 | NO HEATING. The temperature has not increased by the number of degrees specified in the function ”MIN. TEMPERATURE INCREASE” (see back in this section), over the period of time specified in the function MAXIMUM HEATING TIME (see ”SETTINGS 1”). On machines built for washing mops, it can be caused by too low a level in the program stage. The lowest level for a mop program in the main wash with heating is 22 scale units. |

| 10 | NOT DRAINED. When the drain sequence has finished, the water level is still higher than the EMPTY level. |

| 11 | UNBALANCE SENSOR FAULT. The unbalance switch is closed when the machine is starting on a drain sequence. |

| 13 | NO MOTOR COMM. Communication between PCU and motor control unit interrupted or disturbed. |

| 14 | LEVEL CALIBRATION. Every machine has individual level calibration at the factory. If these calibration values are missing or fall outside the limit values, an error warning will be flagged at each program start-up. The program can still be started, however, by pressing START. It will then use standard (default) values, which means that the levels will not be as precise as intended. |

| 15 | EMERGENCY STOP. The emergency stop button has been pressed. |

| 16 | WEIGHT FROM SCALE. Over-/Under-load of scale or weight above limit for maximum allowed weight at wash module start. |

| 17 | DOOR LOCK. Even though the door lock microswitch indicates that the door is locked, the signal from the microswitch which is used to detect when the door is closed is absent. |

| 18 | START NOT ALLOWED. Network does not allow programme start. |

| 19 | MIS COMMUNICATION. Machine has lost contact with network. |

| 20 | INTERLOCK STATUS. The motor control system for frequency-controlled motors (EWD) receives a signal direct from the door lock which indicates that the door really is closed. If this signal is lost, a fault signal is sent to the PCU |

| 21 | I/O COMMUNICATION. Communication between the CPU board and one of the I/O boards interrupted or disturbed. |

| 22 | LOW OIL LEVEL. In machines with an oil lubrication system, indicates low level in the oil container. |

| 23 | PHASE. Incorrect input voltage to external equipment. |

| 24 | PRESSURE SENSOR TILT. Both pressure sensors are active at the same time |

| 25 | PRESSURE SENSOR TIMEOUT. No pressure at the relevant pressure sensor within the maximum time allowed for tilt backwards or forwards. |

| 26 | DOOR SWITCH, TILT. Door closed (S3) is "on" at a time when the machine door is locked open (S25).) |

| 27 | AUT. LEVEL CALIB. The pressure sensor for the water level signals a value that is so different from the empty machine state that the automatic level calibration cannot adjust the level system. |

| 28 | Calibration of level system not done in service mode before use of machine. |

| 31 | HEAT SINK TOO HOT. Temperature of MCU control circuits too high |

| 32 | MOTOR TOO HOT. Motor thermal protection has tripped |

| 33 | NO INTERLOCK. The motor has received a start command from the PCU without receiving an interlock signal from the door lock. The MCU receiving circuitry for the interlock signal is not faulty. |

| 35 | MOTOR SHORTNING. Short-circuit between motor windings or to earth. |

| 36 | INTERLOCK HARDWARE. Fault in MCU receiving circuitry for lock acknowledgement signal |

| 37 | LOW DC VOLTAGE. DC voltage too low |

| 38 | HIGH DC VOLTAGE. DC voltage too high |

| 39 | RIPPEL ON DC BUS. DC level varying too much |

| 40 | LINE INTERRUPT. One phase missing for/at motor control unit |

| 41 | KLIXON CIRCUITS. Hardware fault, temperature monitoring, motor |

| 42 | NO PARAM. SET IN MCU. The motor controller (MCU) (inverter) contains several different parameter sets for different motors. During power up the timer checks that the correct parameter set digit is written into the MCU. If not, the timer will write down the parameter set digit defined in fixed config. If the MCU discovers that no parameter set value is written down into the MCU, the error coce will be displayed. |

| E10 | The appliance does not fill with water properly. |

| E20 | The appliance does not drain the water. |

| E40 | The appliance door is open or not closed correctly. Please check the door! |

| EH0 | The main supply is unstable. Wait until the main supply is stable. |

| E91 | No communication between electronic elements of the appliance. Switch off and switch on again. |

Troubleshooting

Certain problems are due to lack of simple maintenance or oversights, which can be solved easily without calling out an engineer. Before contacting your local Service Centre, please check possible cause of malfunction and solution listed below. Once the problem has been eliminated, press the Start/Pause button to restart the program. If after all checks, the problem persists, contact your local Service Centre.

Malfunction: The washer and dryer does not start

Solution:

- The door has not been closed. (Error code: E40 ) => Close the door firmly.

- The plug is not properly inserted in the power socket. => Insert the plug into the power socket.

- There is no power at the socket. => Please check your domestic electrical installation.

- The Start/Pause touchpad has not been pressed. => Press the Start/Pause touchpad.

- The “Delay Start” has been selected. => If the laundry are to be washed immediately, cancel the “Delay Start”.

- The Main supply is unstable. (If EH0 appears in the display.) => Wait until the main supply is stable. Appliance will start automatically.

Malfunction: The machine does not fill the water

Solution:

- The water tap is closed. (Error code: E10 ) => Open the water tap.

- The inlet hose is squashed or kinked. (Error code: E10 ) => Check the inlet hose connection.

- The filter in the inlet hose is blocked. (Error code: E10 ) => Clean the water inlet hose filter.

- The door is not properly closed. (Error code: E40 ) => Close the door firmly.

Malfunction: The machine does not empty and/or does not spin

Solution:

- The drain hose is squashed or kinked. (Error code: E20 ) => Check the drain hose connection.

- The drain pump is clogged. (Error code: E20 ) => Clean the drain filter.

- The option “Rinse Hold” has been selected. => Press Start/Pause touchpad to drain the water or select spin program.

- The laundry is not evenly distributed in the drum. => Pause the machine and redistribute laundry manually.

Malfunction: There is water on the floor

Solution:

- Too much detergent or unsuitable detergent (creates too much foam) has been used. => Reduce detergent quantity and use correct type of detergent.

- Check whether there are any leaks from one of the inlet hose fittings. It is not always easy to see this as the water runs down the hose; check to see if it is damp. => Check the water inlet hose connection.

- The drain hose is damaged. => Call Service.

Malfunction: Unsatisfactory washing result

Solution:

- Too little detergent or unsuitable detergent has been used. => Increase detergent quantity or use different detergent.

- Stubborn stains have not been treated prior to washing. => Use commercial products to treat the stubborn stains.

- The correct temperature was not selected. => Check if you have selected the correct temperature.

- Excessive laundry load. => Reduce load.

Malfunction: The door will not open

Solution:

- The program is still running. => Wait until the end of cycle.

- There is water in the drum. => You must drain the water to open the door.

- This problem may be caused by a failure of the appliance. => Contact Service. If you need to open the door, please read carefully “Emergency door opening” on next page.

Malfunction: The machine vibrates or is noisy

Solution:

- The transit bolts and packing have not been removed. => Check the correct installation of the appliance.

- The support feet have not been adjusted. => Check the correct levelling of the appliance.

- The laundry is not evenly distributed in the drum. => Pause the machine and redistribute laundry manually.

- There is very little laundry in the drum. => Load more laundry.

- Unstable floors eg. wooden floors. => Refer to relevant paragraph in “Positioning” section.

Malfunction: The machine does not dry or does not dry properly

Solution:

- The “Dry Time” or the “Dryness” degree has not been selected. => Select the drying time or the dryness degree.

- The water tap is not turned on. (Error code: E10 ) => Open the water tap.

- The drain filter is clogged. (Error code: E20 ) => Clean the drain filter.

- The machine is overloaded. => Reduce the laundry load in the drum.

- The selected drying program, time or dryness degree was not suitable for the laundry. => Select the suitable drying program, time or dryness degree for the laundry.

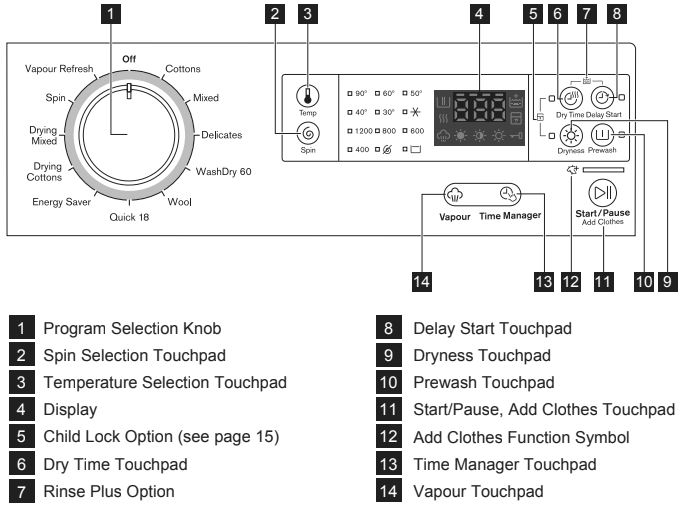

Washer Control Panel

Washer and Dryers Alarm Codes

| Alarm Codes | Solutions |

|---|---|

| E11 | Difficulties in water fill for washing. Tap closed or water pressure too low; Drain tube improperly positioned; Water fill solenoid valve is faulty; Leaks from water circuit on pressure switch; Pressure switch faulty; Wiring faulty; PCB faulty. |

| E12 | Difficulties in water fill for drying. Tap closed or water pressure too low; Drain tube improperly positioned; Water fill solenoid valve is faulty; Leaks from water circuit on pressure switch; Pressure switch faulty; Wiring faulty; PCB faulty. |

| E13 | Water leakage. Drain hose incorrectly positioned; mains pressure insufficient; water fill solenoid faulty; leakage/blockage of pressure switch hydraulic circuit; pressure switch faulty. |

| E21 | Difficulties in draining for washing. Drain tube kinked/clogged/improperly positioned; Drain filter clogged/dirty; Drain pump faulty; Pressure switch faulty; Wiring faulty; PCB faulty. |

| E22 | Difficulties in draining for drying. Drain tube kinked/clogged/improperly positioned; Drain filter clogged/dirty; Drain pump faulty; Pressure switch faulty; Wiring faulty; PCB faulty. |

| E23 | Drain pump triac faulty. Drain pump faulty; Wiring faulty; PCB faulty. |

| E24 | Fault in “sensing” circuit of drain pump triac (wrong input signal to microprocessor) PCB faulty. |

| E31 | Electronic pressure switch circuit faulty (frequency of pressure switch signal out of limits) Electronic pressure switch; Wiring; PCB faulty. |

| E32 | Incorrect calibration of electronic pressure switch (The electronic pressure switch generates a signal with instable frequency during the drain phase). Drain tube kinked/clogged/improperly positioned; Drain filter clogged/dirty; Drain pump faulty; Leaks from water circuit on pressure switch; Pressure switch; Wiring faulty; PCB faulty. |

| E35 | Water overflow. Water fill solenoid faulty; Leaks from water circuit on pressure switch; pressure switch faulty; wiring faulty; PCB faulty. |

| E38 | Pressure chamber blocked (water level does not vary for at least 30 sec. during drum rotation) Motor drive belt broken; Hydraulic circuit pressure switch clogged. |

| E3A | Heating elem. relay sensing faulty (input signal to microprocessor always 0V or 5V) PCB faulty. |

| E41 | Door open (after 15 sec.) Door interlock faulty; wiring faulty; PCB faulty. |

| E42 | Problems of door closure. Door interlock faulty; wiring faulty; PCB faulty. |

| E43 | Interlock power supply triac faulty. Door interlock faulty; wiring faulty; PCB faulty. |

| E44 | Door interlock sensing circuit triac faulty. PCB faulty. |

| E45 | Door interlock sensing circuit triac faulty (wrong input signal to microprocessor) PCB faulty. |

| E52 | No signal from motor tachometric generator. Motor faulty; wiring faulty; PCB faulty. |

| E57 | Inverter is drawing too much current (>15A). Motor-Inverter wiring faulty; Inverter board faulty, Motor faulty. |

| E58 | Inverter is drawing too much current (>4,5A). Motor abnormal operation (overloaded); Motor-Inverter wiring faulty; Motor faulty; Inverter board faulty. |

| E59 | No signal from tachometric generator for three seconds. Motor-Inverter wiring faulty; Inverter board faulty, Motor faulty. |

| E5A | Overheating for heat dissipator for Inverter. Overheating caused by continuous operation or ambient conditions (let appliance cool down); Inverter board faulty. NTC open (on the Inverter board). |

| E5H | Input voltage is lower than 175V. Wiring faulty; Inverter board faulty |

| E5C | Input voltage is too high. Input voltage is too high (measure the masters voltage); Inverter board faulty. |

| E5d | Data transfer error between Inverter and main board. Line interference; Wiring faulty; Main board or Inverter faulty. |

| E5E | Wrong communication between main board and Inverter. Main board-Inverter wiring faulty; Inverter board faulty; Main board faulty. |

| E5F | Inverter board does not start the motor. Wiring faulty; Inverter board faulty; Main board faulty. |

| E61 | Insufficient heating during washing. NTC sensor faulty; heating element faulty; wiring faulty; PCB faulty. |

| E62 | Overheating during washing (temperature higher than 88°C for a time higher than 5 min.) NTC sensor faulty; heating element faulty; wiring faulty; PCB faulty. |

| E66 | Heating element power relay faulty (incongruence between sensing and relay) PCB faulty. |

| E68 | Current dispersion to earth (value of mains voltage different from main value) Current dispersion between between heating element and earth. |

| E69 | Heating element interrupted. Wiring faulty; Heating element for washing interrupted (thermofuse open) |

| E71 | Washing NTC sensor faulty (short- circuited or open) Wiring faulty; Washing NTC sensor faulty; PCB faulty. |

| E72 | Drying condenser NTC sensor faulty (voltage value out of limits, sensor short-circuited or open) Wiring faulty; Drying NTC sensor (condenser) badly positioned or faulty; WD board faulty. |

| E73 | Drying duct NTC sensor faulty (voltage value out of limits, sensor short-circuited or open) Wiring faulty; Drying NTC sensor (duct) badly positioned or faulty; WD board faulty. |

| E74 | Washing NTC sensor badly positioned. Wiring faulty; Washing NTC sensor badly positioned; NTC sensor faulty; PCB faulty. |

| E82 | Error in selector reset position. PCB faulty (Wrong configuration data). |

| E83 | Error in selector reading. PCB faulty (Wrong configuration data. |

| E91 | Communication error between PCB and display board. Wiring faulty; Control/display board faulty: PCB faulty. |

| E92 | Communication incongruence between main PCB- display board (versions not compatible) Wrong control/display board; Wrong PCB (do not correspond to the model). |

| E93 | Incorrect configuration of appliance. PCB faulty; (Incorrect configuration data). |

| E94 | Incorrect configuration of washing cycle. PCB faulty; (Incorrect configuration data). |

| E95 | Communication error between microprocessor and EEPROM. PCB faulty |

| E97 | Incongruence between programme selector and cycle configuration. Faulty PCB (Wrong configuration data). |

| E98 | Communication error between main board - Inverter. Incompatibility between main board and Inverter. |

| E9H | Communication error between microprocessor and FLASH memory. Display board. |

| E9C | Machine configuration error. Display board. |

| E9d | Clock faulty. Display board. |

| E9F | Communication error between PCB and remote devices. Wiring between PCB and Inverter faulty; PCB faulty; Inverter faulty. |

| EA1 | Drum positioning (DSP) faulty. Motor belt broken; Wiring faulty; PCB faulty; DSP sensor faulty. |

| EA6 | DSP door opening faulty. Motor belt broken; Wiring faulty; Drum cover open. Motor faulty; PCB faulty. |

| EC1 | Solenoid valve blocked with flowmeter working. Wiring faulty; Solenoid valve faulty/blocked, PCB faulty. |

| EC3 | Problems with Weight sensor (no signal or out of limits) Wiring faulty; Weight sensor faulty; PCB faulty. |

| Ed1 | Data communication error between WD board and PCB. Wiring faulty between PCB and WD board; WD board faulty; PCB faulty. |

| Ed2 | Drying heating element relay 1 faulty. Wiring faulty between WD board and thermostats; thermostats faulty; WD board faulty, PCB faulty. |

| Ed3 | Drying heating element relay 2 faulty. Wiring faulty between WD board and thermostats; thermostats faulty; WD board faulty, PCB faulty. |

| Ed4 | Relay which commutates power between washing heating element and drying (in the WD board). Wiring faulty; WD board faulty; PCB faulty. |

| Ed6 | No communication between PCB and display board (INPUT). Wiring faulty between PCB and programme display board; PCB faulty. |

| EF1 | Drain filter blocked (drain phase too long) Drain tube blocked/kinked/too high; Drain filter dirty/blocked. |

| EF2 | Excessive detergent dosing (excessive foam during draining) Excessive detergent dosing; drain tube kinked/blocked; Drain filter dirty/blocked. |

| EF3 | Aqua control intervention. Water leaks onto base frame; water control system defective. |

| EF4 | Water fill pressure low, no signal of flowmeter and solenoid valve open. Tap closed; water fill pressure low. |

| EF5 | Unbalanced load. Final spin phases skipped. |

| EF6 | Reset. No action to be performed, if continues replace the PCB. |

| EH1 | Frequency power of appliance out of limits. Power supply problems (incorrect / disturbance); PCB faulty. |

| EH2 | Voltage too high. Power supply problems (incorrect / disturbance); PCB faulty. |

| EH3 | Voltage too low. Power supply problems (incorrect / disturbance); PCB faulty. |

| EHE | Incongruence between safety relay (in the PCB) and the safety “sensing” circuit. Wiring faulty; PCB faulty. |

| EHF | Safety “sensing” circuit faulty (input voltage to microprocessor wrong) PCB faulty. |

Dryer Codes List

Electrolux clothes dryers have error codes that provide users with numerical messages to diagnose appliance issues, ranging from water drainage problems to heating issues. A brief summary of all error codes and the possible cause for each error is presented below.

| Error Codes | Solution |

|---|---|

| E 01 | No water. Water level has not reached set level within time set.After this error message appears and the machine is reset,the machine will try again. |

| E 02 | Open door. Signal from microswitch which checks door status absent during program.After this error message appears and the machine is reset,the machine will try again. |

| E 03 | The input sensor has short circuited. The thermistor that measures air temperature at the drum inlet or the wires running to the sensor has short circuited. |

| E 04 | The output sensor has short circuited. The thermistor that measures air temperature at the drum outlet or the wires running to the sensor has short circuited. |

| E 05 | The fan motor has overheated (Motor 1). The heat protection contact in the motor, or its cable stem, is open. |

| E 06 | The drum motor has overheated (Motor 2). The heat protection contact in the motor, or its cable stem, is open. |

| E 07 | External error |

| E 08 | Machine overheated. Protection thermostats for inlet and outlet air. One of the protection thermostats has opened due to overheating. |

| E 09 | Filter lid open |

| E 10 | Incorrect programming. One or more parameters are incorrect or is missing. |

| E 11 | Drying error with RMC program. The longest permitted RMC time has been exceeded. (Applies only to machines with RMC) |

| E 12 | Drying error with autostop program. The longest permitted automatic stop time has been exceeded. (Applies only to machines with automatic stop). |

| E 13 | Drying error with time program. The set drying time is longer than longest permitted. (Applies to tumble dryers that are connected to a payment system). |

| E 14 | Gas error, push gas reset button. No flame has been detected. (Applies only to gas heated tumble dryers). |

| E 15 | No vacuum detected. The vacuum/pressure switch does not close within 12 seconds of the tumble dryer starting. |

| E 16 | Vacuum sensor has short circuited. The vacuum/pressure switch was already closed when an attempt was made to start the tumble dryer. |

| E 17 | The input sensor has disconnected. The inlet thermistor, or its wires, is open. |

| E 18 | The output sensor has disconnected. The outlet thermistor, or its wires, is open. |

| E 19 | Machine has lost contact with network. |

| E 20 | Machine is out of operation. The tumble dryer has been deactivated by the PC software. |

| E 21 | Network error, no polling CMIS. The computer has not called the tumble dryer during the timeout period. |

| E 22 | Network error, no polling CBT. The computer has not called the tumble dryer during the timeout period. |

| E 23 | Incorrect input voltage to external equipment. |

| E 24 | Condensate container is full. The condensate container is full and the pump is not operating. |

| E 25 | Damper output air is not closed correct (Applies only to Clean Room tumble dryers). |

| E 26 | Damper output air is not open correct (Applies only to Clean Room tumble dryers). |

| E 27 | Hepa filter pressure warning (Applies only to Clean Room tumble dryers). |

| E 28 | Input temperature oscillating. |

| E4A | The drying time has exceeded programtime for cycle. |

| E 5B | No heat. |

| E 68 | One of the keys (buttons) isstuck closed (active). |

| E 8C | High limit thermostat has trip to many timesin a certain amount of time. |

| E AF | Microcontroller has been reset by Watchdog timer. Clear code, exit mode and start dryer. If problem persists, replace electronic control. |

| E31 | Conductimetric sensing oscillation frequency to high. The conductimetric electronic circuit has an oscillation frequency out of range. Main board defective. |

| E32 | Conductimetric sensing oscillation frequency to low. The conductimetric electronic circuit has an oscillation frequency out of. Main board defective wiring defective. |

| E51 | Motor triac failure. Incongruence between motor triac sensing and triac status. |

| E52 | Motor thermal cut off. Incongruence between motor triac sensing and triac status. |

| E53 | Motor triac sensing failure. Incongruence between motor triac sensing and triac status. |

| E54 | Motor jammed. Motor cannot move. |

| E61 | Heating timeout. NTC value doesn’t changed after some minutes since every heating cycle step start. |

| E62 | Compressor relay failure. Incongruence between compressor sensing and relay driving after N trials. |

| E63 | Compressor automatic thermostat. Incongruence between compressor sensing and relay driving. |

| E64 | Compressor sensing failure. Incongruence between compressor sensing and relay status. |

| E65 | Main Fan relay failure. Incongruence between main fan sensing and relay driving after N trials. |

| E66 | Main fan automatic thermostat. Incongruence between main fan sensing and relay driving. |

| E67 | Main fan sensing failure. Incongruence between main fan sensing and relay status. |

| E71 | Drying NTC1 failure. Voltage value out of limit (open circuit or short circuit) |

| E72 | Drying NTC2 failure. Voltage value out of limit (open circuit or short circuit) |

| E82 | Wrong selector reset position detection. Reset position code read on selector out of power fail management. |

| E93 | Machine configuration error. Incongruent values on configuration data at power-on (checksum error) |

| E94 | Cycle Configuration error. Reset Incongruence values on configuration data at power-on (checksum error) |

| E95 | Communication error between microprocessor and external EEPROM. Error detected during external EEPROM data read/write. |

| E97 | SCF – CTF mismatch error. CTF file doesn’t contain all programs specified into SCF file. Wrong configuration. |

| EB1 | Power supply frequency out of limits. Power supply period lower/higher than configured values. |

| EB2 | Power supply voltage too high. MAIN_V sensing input voltage value on microprocessor to 5V. |

| EB3 | Power supply voltage too low. MAIN_V sensing input voltage value lower than configured value. |

Dryer Care and Cleaning

- Before cleaning the dryer interior, unplug the electrical power cord to avoid electrical shock hazards.

- Do not use any type spray cleanser when cleaning the dryer interior. Hazardous fumes or electrical shock could occur.

Inside

- Clean the lint filter after every load. Lint buildup on the filter restricts air flow, which causes longer drying times. The filter is located at the bottom of the door opening. Remove by pulling straight up. Remove the lint and replace the filter.

- Occasionally a waxy build-up may form on the lint filter and/or moisture sensing bars from using dryer-added fabric softener sheets. To remove this build-up, wash them with warm, soapy water. Dry the filter thoroughly and replace. Do not operate the dryer without the lint filter in place.

- If the dryer drum becomes stained from noncolorfast fabrics, clean the drum with a damp cloth and a mild liquid household cleanser. Remove cleanser residue before drying the next load.

- Every 18 months an authorized servicer should clean the dryer cabinet interior and exhaust duct. These areas can collect lint and dust over time. An excessive amount of lint build-up could result in inefficient drying and possible fire hazard.

Outside

- Clean the cabinet with mild soap and water. Never use harsh, gritty or abrasive cleansers.

- If the cabinet becomes stained, clean with diluted chlorine bleach (1 part bleach to 8 parts water). Rinse several times with clear water.

- Remove glue residue from tape or labels with a mixture of warm water and mild detergent. Or, touch residue with the sticky side of the tape or label.

- When cleaning chrome parts use a window cleaner with ammonia or mild soap and water.

- Before moving the dryer, place a strip of cardboard or thin fiberboard under the front leveling legs to prevent damage to the floor.

Dryer Troubleshooting

Common Drying Problems: Many drying problems involve poor cleaning results, poor soil and stain removal, residues of lint and scum, and fabric damage. For satisfactory drying results, follow these suggestions provided by The Soap and Detergent Association.

| Problem | Possible Cause |

|---|---|

| Greasy, oily stains | Fabric softener sheet. Rub fabric softener stains with bar soap. Rinse and rewash. |

| Lint | Overdrying causes static electricity. Reduce load size and rewash using liquid fabric softener in the final rinse. • Or, add a fabric softener sheet and tumble without heat. |

| Pilling (Fibers ball up and cling to fabric) | Overdrying. Use a lint brush or shaver to remove pills. |

| Shrinking | Temperature too high. Irreversible condition. |

| Wrinkling | Overloading. Reduce load size and tumble at medium or low heat for 5-10 minutes. |

| Dryer does not start. | Electrical power cord is not securely plugged in or plug may be loose. Make sure the plug fits tightly in wall outlet. |

| LCD displays DEMO MODE | Dryer has been programmed to temporarily perform a repeating demo cycle. To return to the factory default settings, select RESET in set prefs under the options scroll buttons. |

| Dryer runs but won’t heat | There are 2 house fuses in the dryer circuit. If 1 of the 2 fuses is blown, the drum may turn but the heater will not operate. (electric models) Replace fuse. |

| Drying cycle takes too long, outside of the dryer feels too hot or smells hot | Lint filter is clogged with lint. Make sure all lint has been removed from the dryer lint filter before starting each cycle. |

| Excessive wrinkling | Dryer is overloaded. Do not overload. |

| Scratching or chipping of the drum finish | Foreign objects such as coins, pins, clips or buttons are inside the dryer. Always remove foreign objects from pockets before laundering. Remove objects from drum and restart dryer. |

Manual Pdf

Download Electrolux Wave-Touch Front-Load Gas and Electric Dryer 137018100 A Use And Care Manual Pdf