Siemens is currently listed as the largest industrial manufacturer in Europe, offering the East and west a taste of what they have to offer. Working on offering some of the best appliances there are in the market, they offer customers a chance to enjoy effective and efficient working daily.

Siemens washing machines were once a basic choice that now offers you all the services in a single machine. Offering you everything from semi-automatic to fully automatic appliances so you can easily choose one that offers you the perfect service required based on your personal choices.

Siemens has made a name for itself in the world as one of the best appliance manufacturers and sellers around the world. Making it a great choice for anyone looking for a reliable and trusted brand appliance. That being said, every piece of technology is prone to errors so when you see an error code on your Siemens washing machine simply note it down and match it using the error codes guide below.

Most Common Codes

| Error codes | Cause |

|---|---|

| F01 | The door of the loading hatch is not closed |

| F02 | Water is not supplied |

| F03 | Problems with draining the water |

| F04 | Water leakage occurred |

| F16 | The hatch door is not closed |

| F17 | Time of water intake exceeded |

| F18 | Water drain time exceeded |

| F19 | Water heating time exceeded |

| F20 | Unexpected heating |

| F21 | Control system malfunction |

| F22 | NTC sensor fault |

| F23 | Aquastop activated |

| F25 | Malfunction of the Aqua sensor |

| F26 | Analog pressure sensor malfunction |

| F27 | Error setting pressure sensor |

| F28 | Flow sensor malfunction |

| F29 | No water flow in the flow sensor detected |

| F31 | Maximum water level exceeded |

| F34 | The door lock does not close |

| F36 | The lock system is fault |

| F37 | Faulty NTC (temperature sensor) |

| F38 | Fault NTC |

| F40 | Synchronization error |

| F42 | Uncontrolled high engine speed |

| F43 | Critical error |

| F44 | No reverse rotation occurs |

| F59 | 3D Sensor |

| F60 | Flow sensor, too high or too low |

| F61 | Wrong door signal |

| F63 | Functional protection problem |

| F67 | Card encoding error |

| E02 | Motor problem |

| E67 | Incorrect module encoding |

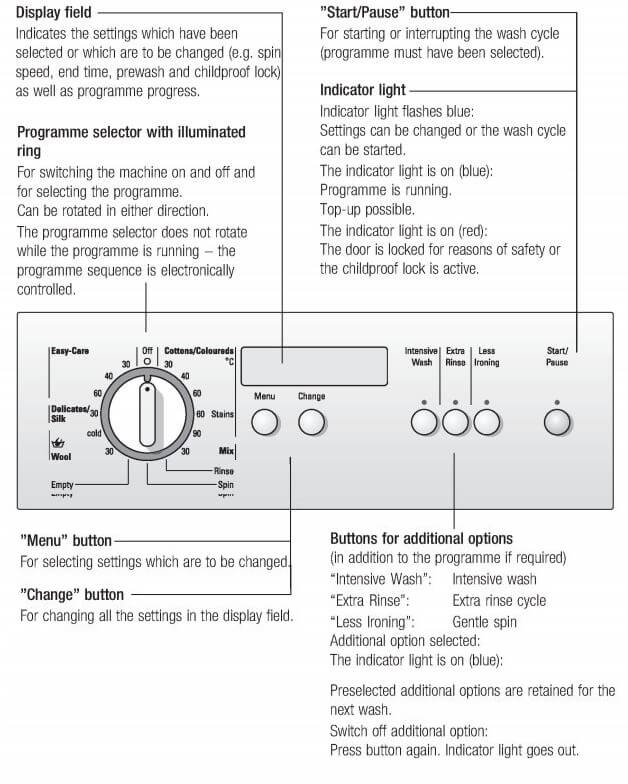

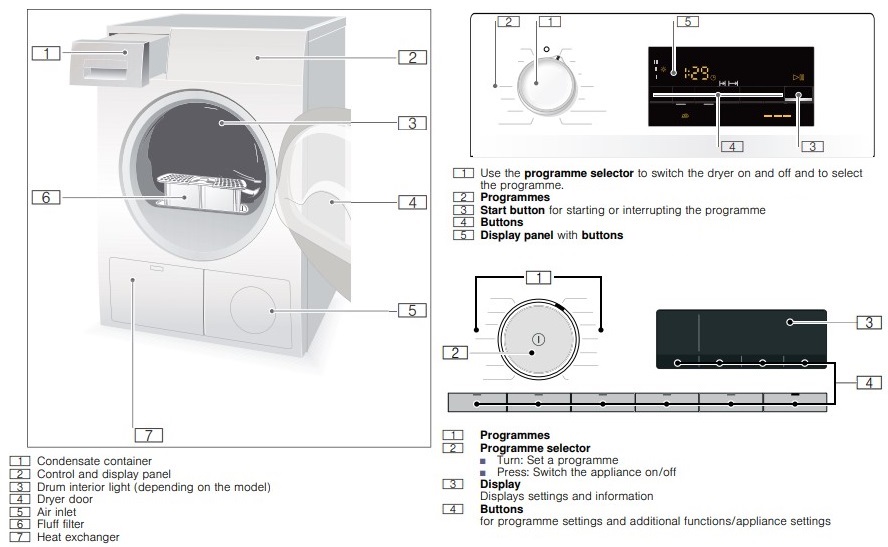

Control Panel

Fault Displays

Text in display field: ”Water tap closed?”

Possible cause:

- Water tap not turned on.

- Supply hose kinked or trapped.

- Strainer in supply hose clogged.

- Water pressure too low.

Action:

- Turn on water tap. Programme continues.

- Eliminate the cause.

- Clean the filter.

- Eliminate the cause.

Text in display field: ”Pump blocked?”

Possible cause:

- Loose debris is blocking the pump.

- The water drainage pipe and/or drain hose is blocked.

Action:

- Clean the pump,

- Clean the water drainage pipe and/or drain hose.

Text in display field: ”Aqua—Stop activated”

Possible cause: Water in the base pan; appliance leaking.

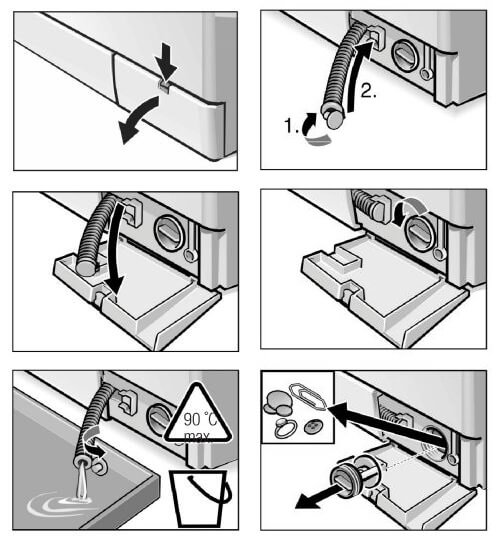

Cleaning the drain pump

This is necessary if the washing solution has not been completely drained. The pump is blocked by either loose debris or fluff which accumulates if fluff-giving fabrics are washed.

Allow the hot washing solution to cool. Keep Children and pets away.

- Turn the programme selector to ”Off”.

- Open service flap.

- Remove the drain hose from its holder and pull the hose out of the housing.

- Remove sen/ioe flap.

- Pull down the Closing cap and allow the washing lye to flow into a suitable container.

- Push up the Closing cap (1st) and place the drain hose back in its holder (2nd).

- Carefully remove the pump cap. A little residual water will flow out.

- Remove any loose debris / fluff from inside the pump and Clean the pump. The pump impeller must be able to rotate. Clean any residual lye or fluff from the thread of the pump cap and pump housing.

- Attaoh and tighten the pump cap.

- Insert and Close sen/ioe flap.

- Pour litre/1 3/4 pt of water into Chamber 2.

- Select the ”Empty” programme.

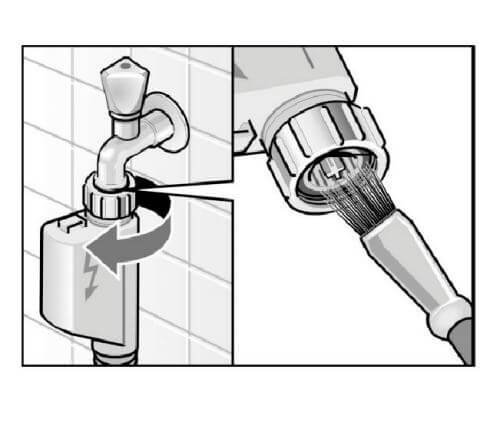

Cleaning water inlet strainers

This is necessary if very little or no water flows into the washing machine.

First release the water pressure in the supply hose:

- Turn offt he water tap.

- Turn the programme selector to any programme (except ”Spin” and ”Empty”).

- Press ”Start/Pause” button and wait for ”Water tap Closed?” message.

- Turn the programme selector to ”Off”.

- Disconnect the hose from the water tap.

- Clean filter with a small brush or paint brush.

- Connect the hose.

- Turn on water tap.

- Check whether water is coming out of the end of the hose.

If water is still discharged, check that the strainer is attached properly.

Caution: Descaling agents contain acids which can attack parts of the washing machine and disoolour the laundry.

Dryer Codes List

| Error Codes | Meaning |

|---|---|

| E01 | Lint filter dirty. Clean filter. Switch off/switch on again. |

| Exhaust air duct is blocked or too long. Clean exhaust air duct. Reduce exhaust air duct to maximum length. Switch off/switch on again. | |

| Fault in program sequence or malfunction. Switch off dryer, leave to cool down for 30 min, switch on again. Restart program. | |

| The room/cabinet is not adequately ventilated. Provide an adequate supply of fresh air. Switch off/switch on again. | |

| E03 | Moisture sensor dirty. Clean moisture sensor. Switch off/switch on again. |

| Exhaust air duct is blocked or too long. Clean exhaust air extraction. Reduce exhaust air duct to maximum length. Switch off/switch on again. | |

| Lint filter dirty. Clean filter. Switch off/switch on again. | |

| Laundry was too wet. Spin laundry at higher speed in the washing machine. Switch off/switch on again. | |

| Unsuitable program selected. Select program with aid of the program selection table.. Switch off/switch on again. | |

| Maximum drying time was exceeded. Clean lint filter. Check exhaust air extraction. Spin laundry at a higher speed in your washer. | |

| Motor limit temperature was exceeded. Switch off dryer, leave to cool down for 30 min. Switch on again. start program. | |

| 000 | Fault in program sequence or malfunction. Switch off dryer, leave to cool down for 30 min, switch on again. Restart program. |

Cleaning the lint filter

A dirty filter extends the drying time and increases energy consumption. The filter should be cleaned before and after each drying process, however at the latest when the “lint filter” indicator light illuminates. If the “lint filter” indicator light illuminates during a drying program and a warning signal is emitted, clean the filter immediately and check the exhaust duct.

- Switch off the dryer. Program selector to “off”.

- Open the door.

- Remove the filter.

- Remove lint by stroking your hand over the filter.

- Insert the filter.

- Close the door.

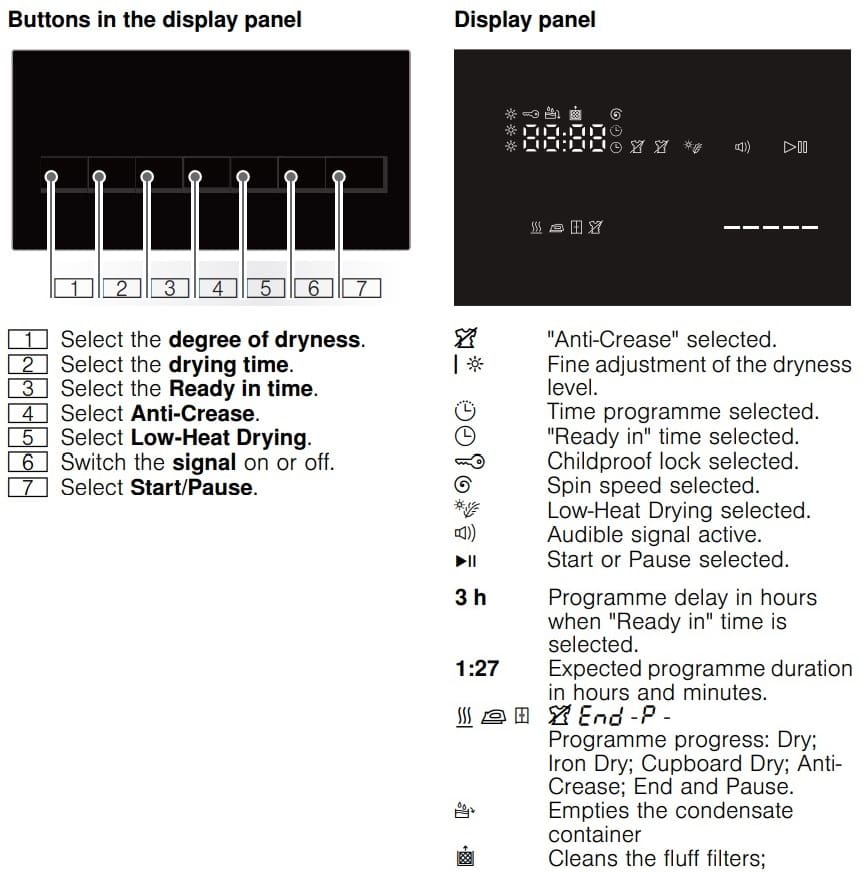

Dryer Display Panel

Dryer Button Meaning

| Buttons | Explanations |

|---|---|

| Fine Adjust | If the laundry is too damp after drying, you can finely adjust the dryness level e.g. Cupboard Dry. If you have adjusted the dryness level, the setting for all programmes with a selectable dryness level is retained even after the dryer is switched off. Note: The higher the degree of dryness, the longer the programme duration. |

| Drying Time | Adjust the programme length for the time programmes. Between 20 minutes and 3 hours, in 10-minute increments. |

| Finished In | The programme will end in 1-24 hrs. Set the "Ready in" time in increments of one hour to delay the start of the programme. The required number of hours after the programme ends is displayed in the display panel. |

| Less Ironing | The drum moves the laundry at regular intervals for 60 or 120 minutes after drying, in any programme, to prevent creasing. |

| Gentle Dry | Reduced temperature for delicate fabrics, e.g. polyacrylic or elastane. Selecting the button will extend the drying time. |

| Buzzer | A signal sounds after the programme has ended. |

| 3 sec. (Childproof lock 3 sec.) | Press and hold the "Ready in" time button and the drying time button at the same time for 3 seconds to activate or deactivate the childproof lock. |

| Start/Reload | Starts or pauses the programme. |

Dryer Troubleshooting

If you cannot rectify the fault yourself by turning the appliance off and then on again, please contact our after-sales service.

| Trouble | Solution |

|---|---|

| Appliance does not start. | Check the mains plug and the fuses. |

| Creasing. | Load exceeded or incorrect programme selected for a type of fabric. |

| Remove laundry from the drum as soon as the drying programme has finished. Creasing occurs when clothing is left in the drum. | |

| Water is leaking out. | The appliance may be positioned at an angle. Level the appliance. |

| In the base unit, make sure that: -The heat exchanger cover is properly locked. -There is no dirt or debris on the heat exchanger cover's seal. | |

| If the optional drain hose is installed, make sure that the drain hose is correctly connected. | |

| The appliance is paused but the drum is turning. | The appliance has detected a high temperature and has started the CoolDown process. Temperature regulation can take up to 10 minutes. You can cancel the CoolDown process at any time by opening the door. |

| Programme duration displayed changes as drying progresses. | Not a fault. The moisture sensor measures the residual moisture in the laundry and adjusts the programme duration (with the exception of timed programmes). |

| Laundry is not dried properly or is still too damp. | After the programme has ended, warm laundry feels damper than it actually is. Spread out the laundry and let it cool down. |

| Adjust the drying time or increase the degree of dryness. This will extend the drying time but the temperature will remain the same. | |

| Select a timed programme to add extra drying time for laundry that is still damp. | |

| Drying time too long. | The appliance may have fluff in it. This will increase the required drying time. -Clean the base unit. -Run a complete drying cycle with a load weighing more than 3 kg. Make sure the laundry has not been pre-dried. |

| The heat exchanger may have fluff in it. | |

| If the air inlet on the appliance is blocked or not fully open, this may increase the drying time. Make sure the air inlet remains unobstructed. | |

| Unpleasant odour in the appliance | Run the intensive appliance care programme. |

| Humidity in the room is increasing. | Make sure the room is sufficiently ventilated. |

| Unusual noises when drying. | When drying is in progress, the pump and compressor generate noise when operating normally. This does not indicate that the appliance is malfunctioning. |

| The appliance feels cold despite drying. | Not a fault. The appliance can dry effectively at low temperatures using a heat pump. |

| Drying programme is stopped. | If the drying programme is stopped due to a power failure, restart the programme or remove the laundry and spread it out. |

| Residual water in the condensation container despite the appliance being connected to the drain hose. | If the optional drain hose is installed, residual water remains in the condensation container due to the appliance's self-cleaning function. |

Manual Pdf

source: siemens-home.bsh-group.com