Aeg washing machine error codes are essential indicators for users to oversee their appliance’s functionality. These codes offer swift diagnostic information for a range of issues, including water supply problems and electrical faults. Comprehending these error codes is critical for users to effectively troubleshoot and maintain their washing machines, ensuring prolonged and efficient operation.

Error Messages

| Error Code | Problem |

|---|---|

| E10 | The appliance does not fill with water properly. |

| E11 | Poor fill before wash cycle. Tap off or water pressure too low; Drain hose improperly positioned; Fill valve is defective; Leaks on pressure switch; Pressure switch failed; Wiring fault; Main board defective. Cycle is paused with door locked Start |

| E12 | Difficulty in fill during drying (maximum time 3 min. fill in drying during the wash load phase) Tap off or water pressure too low; valve failed; pressure switch water circuit; pressure switches; wiring; main PCB. Cycle is paused |

| E13 | Water leaks. Drain hose improperly positioned; Water pressure too low; Fill valve is defective; Water circuit on pressure switch is leaking or blocked; Pressure switch faulty. Cycle is paused with door locked Start |

| E20 | The appliance does not drain the water |

| E21 | Poor draining. Drain hose kinked/clogged/improperly positioned; Drain filter clogged/dirty; Drain pump faulty; Pressure switch faulty; Wiring faulty; Main board faulty; Current leak between heating element and ground. Cycle is paused Start |

| E22 | Difficulty in fill during drying or drying condenser blocked (pressure switch closed on “FULL”) Drain hose kinked; filter blocked: drying condenser blocked; drain pump faulty; pressure switches faulty; wiring; main circuit board faulty; Current leakage between heater and ground. Cycle is paused Start |

| E23 | Defective triac for drain pump. Drain pump faulty; Wiring faulty; Main board faulty. Emergency drain procedure Cycle stops with door unlocked OFF/reset |

| E24 | Malfunction in sensing circuit on triac for drain pump. Main board faulty. Emergency drain procedure. Cycle stops with door unlocked OFF/reset |

| E31 | Malfunction in pressure switch circuit (frequency of signal from pressure switch out of limits) Pressure switch faulty; Wiring; Main PCB faulty; Cycle stops with door locked OFF/reset |

| E32 | Electronic pressure switch improperly calibrated (level on electronic pressure switch differs from 0-66 mm after initial calibration drain and when anti-boiling pressure switch is on “empty”). Tap is off or water pressure is too low; Fill valve faulty; Water circuit on pressure switches; pressure switches; Wiring; PCB faulty; Cycle is paused Start |

| E33 | Inconsistency between level on electronic pressure switch and level on anti-boiling pressure switch 1-2 (fault persists for at least 60 sec.). Pressure switch defective; Current leak between heating element and ground; Heating element; Wiring faulty; Main board faulty. Water circuit; Emergency drain procedure Cycle stops with door unlocked OFF/reset |

| E34 | Inconsistency between level on electronic pressure switch and level on anti-boiling pressure switch 2 (fault persists for at least 60 sec.). Pressure switch faulty; Electrical current leak between heating element and ground; Heating element faulty; Wiring faulty; Main board faulty. Water circuit; Emergency drain procedure Cycle stops with door unlocked OFF/reset |

| E35 | Overflow. Fill valve is faulty; Leaks from water circuit on pressure switch; Pressure switch defective; Wiring defective; Main board defective. Cycle stops. Emergency drain procedure. Drain pump continues to operate (5 min. on, then 5 min. off, etc.). OFF/reset |

| E36 | Sensing circuit on anti-boiling pressure switch 1 defective Main board faulty. Cycle stops with door locked OFF/reset |

| E37 | Sensing circuit on anti-boiling pressure switch 2 defective. Main board faulty. Cycle stops with door locked OFF/reset |

| E38 | Internal pressure takeoff is blocked (water level does not change for at least 30 sec. of drum rotation). Water circuit on pressure switches; Pressure switches; Motor belt broken; Heating phase is skipped |

| E39 | Defective HV sensing on anti-overflow system Main board faulty. Cycle stops with door locked OFF/reset |

| E40 | The appliance door is open or not closed correctly. Please check the door! |

| E3A | Faulty sensing by heating resistance relay. Main board defective. Cycle stops with door locked OFF/reset |

| E41 | Door unlocked. Door lock faulty; Wiring faulty; Main board faulty. Cycle is paused Start |

| E42 | Problem closing the door. Door lock faulty; Wiring faulty; Main board faulty. Cycle is paused Start |

| E43 | Defective triac supplying power to door delay system. Door lock unit faulty; Wiring faulty; Main board faulty. (Emergency drain procedure) Cycle stops OFF/reset |

| E44 | Defective sensing by door delay system. Main board faulty. (Emergency drain procedure) Cycle stops OFF/reset |

| E45 | Defective sensing by triac on door delay system. Main board faulty. (Emergency drain procedure) Cycle stops OFF/reset |

| E51 | Motor power supply triac short-circuited. PCB faulty; current leakage from motor or from wiring loom. Cycle blocked, door locked (after 5 attempts) OFF/reset |

| E52 | No signal from motor tachometric generator. Motor faulty; wiring faulty; PCB faulty Cycle blocked, door locked (after 5 attempts) OFF/reset |

| E53 | Motor triac sensing circuit faulty. PCB faulty. Cycle blocked, door locked OFF/reset |

| E54 | Motor relay contacts sticking. PCB faulty; current leakage from motor or from wiring Cycle blocked, door locked (after 5 attempts) OFF/reset |

| E61 | Insufficient heating during washing. NTC sensor faulty; heating element faulty; wiring faulty; PCB faulty. The heating phase is skipped |

| E62 | Overheating during washing. NTC sensor faulty; heating element faulty; wiring faulty; PCB faulty. Safety drain cycle Cycle stopped with door open OFF/reset |

| E66 | Heating element power relay faulty. PCB faulty; current leakage from heating element to ground. Safety drain cycle Cycle stopped with door open OFF/reset |

| E71 | NTC sensor for wash cycle defective. Faulty NTC sensor; Wiring faulty; Main board faulty. Heating is skipped Start |

| E72 | Fault in NTC sensor on drying condenser (voltage out of range = short-circuit, open circuit) Drying NTC sensor (condenser) faulty; wiring faulty; main circuit board faulty. Heating is skipped Start |

| E73 | Fault in NTC sensor on drying duct (voltage out of range = short-circuit, open circuit) Drying NTC sensor (duct) faulty; wiring faulty; main circuit board faulty. Heating is skipped Start |

| E74 | NTC sensor for wash cycle improperly positioned. NTC sensor incorrectly positioned; Faulty NTC sensor; Wiring defective; Main board faulty. Heating is skipped Start |

| E82 | Error in selector reset position. PCB faulty (Wrong configuration data). Selector, wiring faulty OFF/reset |

| E83 | Error in reading selector. PCB faulty (Wrong configuration data). Selector, wiring Cycle cancelled |

| E84 | "Sensing" circuit on circulation pump triac faulty (input signal to processor always 0V or 5V) PCB Drain, cycle blocked (door open) OFF/reset |

| E85 | Circulation pump faulty (incongruency between status of "sensing" circuit on circulation pump and status of TRIAC) Circulation pump; wiring; main PCB Drain, cycle blocked (door open) OFF/reset |

| E91 | Communication incongruence between main PCB- display board (versions not compatible) Wiring faulty; Faulty control/display board Main PCB faulty. Cycle interrupted |

| E92 | Communication incongruence between main PCB- display board (versions not compatible) Wrong control/display board; Wrong PCB (do not correspond to the model). Cycle interrupted |

| E93 | Incorrect configuration of appliance. Incorrect configuration data; PCB faulty. Cycle interrupted OFF/reset |

| E94 | Incorrect configuration of washing cycle. Incorrect configuration data; PCB faulty. Cycle interrupted OFF/reset |

| E95 | Communication error between microprocessor and EEPROM PCB faulty. Cycle interrupted OFF/reset |

| E97 | Incongruence between programme selector and cycle configuration. Faulty PCB (Wrong configuration data). Cycle interrupted OFF/reset |

| EB1 | Frequency of appliance incorrect. Power supply problems (incorrect / disturbance); PCB faulty. Cycle interrupted |

| EB2 | Voltage too high. Power supply problems (incorrect / disturbance); PCB faulty. Cycle interrupted |

| EB3 | Voltage too low. Power supply problems (incorrect / disturbance); PCB faulty. Cycle interrupted |

| EC1 | Solenoid valve inoperative but flow meter operating. Main board faulty, Fill valve faulty Cycle stops with door locked (after 5 attempts). OFF/reset |

| EC2 | Signal from turbidity sensor out of limits. Turbidity sensor faulty, Main board faulty, Wiring faulty Start/reset |

| EC3 | Signal from weight sensor out of limits. Weight sensor faulty, Main board faulty, Wiring faulty Start/reset |

| EF0 | The anti-flood device is on. Disconnect the appliance and close the water tap. Contact the Authorised Service Centre. |

| EF1 | Drain filter blocked (too long drain phase) Drain tube blocked/kinked/too high; Drain filter dirty/blocked. Warning displayed at the end of cycle (specific LED) |

| EF2 | Overdosing of detergent (too much foam during drain phases) Excessive detergent dosing; drain tube kinked/blocked; Drain filter dirty/blocked. |

| EF3 | Control water intervention. Water leakage on the base; faulty water control device. Water drain and cycle blocked OFF/reset |

| EF4 | Low pressure of water fill, no signal of flow meter and solenoid open Tap closed, low water fill pressure ... Reset |

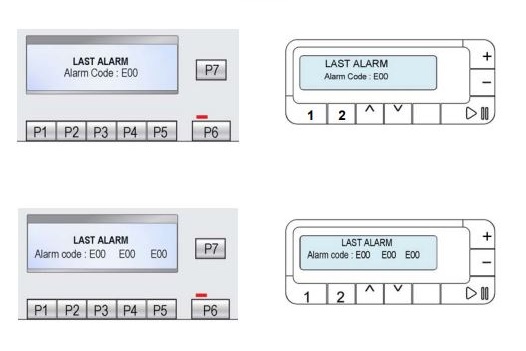

| E00 | No alarm |

| EH0 | The mains supply is unstable. Wait until the mains supply is stable. |

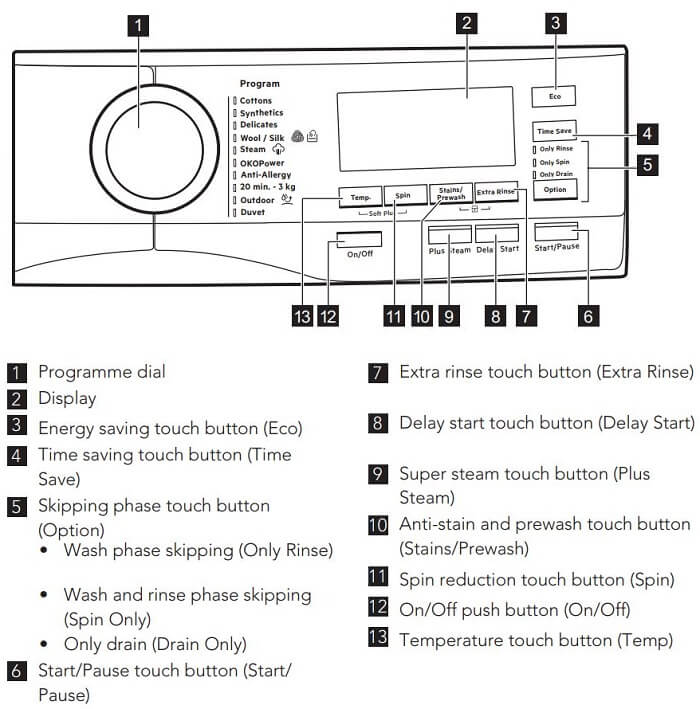

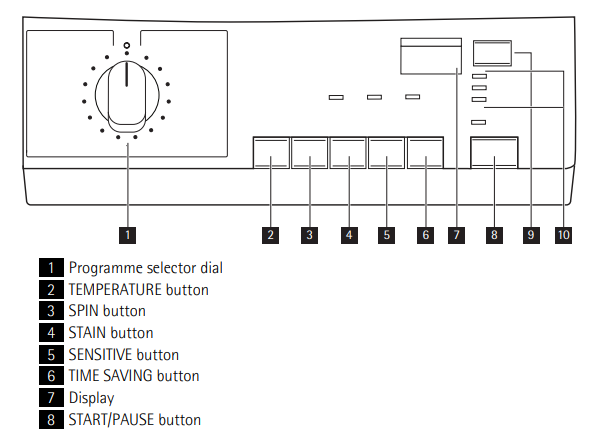

Control Panel Description

LAVAMAT Series Codes

- C1: Not filling/ too slow fill

- C2: Not pumping/too slow pump output

- C3: Aqua control activated

- C7: Not heating

- C8: NTC fault

- C9: Tacho or motor fault

- CA: Motor triac short circuit

- CD: Door lock faulty

- CE: Water distributor fault, this machine has a small motor in the dispenser to select the Compartment to fill through, this in turn operates a micro switch inside the dispenser.

- CF: EPROM fault Some of these faults are locked in and will return even if machine is disconnected; the only way to clear them is to run the test programme. Hold in Pre wash and soak button while turning rotary knob to gentle spin.

LAVAMAT 8 Series Codes

- CO: lmbalance between both Pressure Switches, Heater or wiring fault.

- C1: No water in, valve at fault or low pressure.

- C2: Pump blockage, pump open circuit, drain blockage.

- C3: Safety flood device operated, pump fault, module fault.

- C4: Pump fault.

- C5: Overheat sensor on main motor.

- C6: Pressure switch fault.

- C7: Heater or heater relay fault.

- C8: NTC fault.

- C9: Tacho fault.

- CA: MOS-FET transitor defective.(Replace main module)

- CB: Overfill/level fault or inlet valve.

- CC: PTC for MOS-FET transistor fault, main motor fault.

- CD: Door Interlock fault.

- CF: Checksum EEPROM fault, configuration error on module.

Washer and Dryers Alarm Codes and Solutions

| Alarm Codes | Solutions |

|---|---|

| E11 | Difficulties in water fill for washing. Tap closed or water pressure too low; Drain tube improperly positioned; Water fill solenoid valve is faulty; Leaks from water circuit on pressure switch; Pressure switch faulty; Wiring faulty; PCB faulty. |

| E12 | Difficulties in water fill for drying. Tap closed or water pressure too low; Drain tube improperly positioned; Water fill solenoid valve is faulty; Leaks from water circuit on pressure switch; Pressure switch faulty; Wiring faulty; PCB faulty. |

| E13 | Water leakage. Drain hose incorrectly positioned; mains pressure insufficient; water fill solenoid faulty; leakage/blockage of pressure switch hydraulic circuit; pressure switch faulty. |

| E21 | Difficulties in draining for washing. Drain tube kinked/clogged/improperly positioned; Drain filter clogged/dirty; Drain pump faulty; Pressure switch faulty; Wiring faulty; PCB faulty. |

| E22 | Difficulties in draining for drying. Drain tube kinked/clogged/improperly positioned; Drain filter clogged/dirty; Drain pump faulty; Pressure switch faulty; Wiring faulty; PCB faulty. |

| E23 | Drain pump triac faulty. Drain pump faulty; Wiring faulty; PCB faulty. |

| E24 | Fault in “sensing” circuit of drain pump triac (wrong input signal to microprocessor) PCB faulty. |

| E31 | Electronic pressure switch circuit faulty (frequency of pressure switch signal out of limits) Electronic pressure switch; Wiring; PCB faulty. |

| E32 | Incorrect calibration of electronic pressure switch (The electronic pressure switch generates a signal with instable frequency during the drain phase). Drain tube kinked/clogged/improperly positioned; Drain filter clogged/dirty; Drain pump faulty; Leaks from water circuit on pressure switch; Pressure switch; Wiring faulty; PCB faulty. |

| E35 | Water overflow. Water fill solenoid faulty; Leaks from water circuit on pressure switch; pressure switch faulty; wiring faulty; PCB faulty. |

| E38 | Pressure chamber blocked (water level does not vary for at least 30 sec. during drum rotation) Motor drive belt broken; Hydraulic circuit pressure switch clogged. |

| E3A | Heating elem. relay sensing faulty (input signal to microprocessor always 0V or 5V) PCB faulty. |

| E41 | Door open (after 15 sec.) Door interlock faulty; wiring faulty; PCB faulty. |

| E42 | Problems of door closure. Door interlock faulty; wiring faulty; PCB faulty. |

| E43 | Interlock power supply triac faulty. Door interlock faulty; wiring faulty; PCB faulty. |

| E44 | Door interlock sensing circuit triac faulty. PCB faulty. |

| E45 | Door interlock sensing circuit triac faulty (wrong input signal to microprocessor) PCB faulty. |

| E52 | No signal from motor tachometric generator. Motor faulty; wiring faulty; PCB faulty. |

| E57 | Inverter is drawing too much current (>15A). Motor-Inverter wiring faulty; Inverter board faulty, Motor faulty. |

| E58 | Inverter is drawing too much current (>4,5A). Motor abnormal operation (overloaded); Motor-Inverter wiring faulty; Motor faulty; Inverter board faulty. |

| E59 | No signal from tachometric generator for three seconds. Motor-Inverter wiring faulty; Inverter board faulty, Motor faulty. |

| E5A | Overheating for heat dissipator for Inverter. Overheating caused by continuous operation or ambient conditions (let appliance cool down); Inverter board faulty. NTC open (on the Inverter board). |

| E5H | Input voltage is lower than 175V. Wiring faulty; Inverter board faulty |

| E5C | Input voltage is too high. Input voltage is too high (measure the masters voltage); Inverter board faulty. |

| E5d | Data transfer error between Inverter and main board. Line interference; Wiring faulty; Main board or Inverter faulty. |

| E5E | Wrong communication between main board and Inverter. Main board-Inverter wiring faulty; Inverter board faulty; Main board faulty. |

| E5F | Inverter board does not start the motor. Wiring faulty; Inverter board faulty; Main board faulty. |

| E61 | Insufficient heating during washing. NTC sensor faulty; heating element faulty; wiring faulty; PCB faulty. |

| E62 | Overheating during washing (temperature higher than 88°C for a time higher than 5 min.) NTC sensor faulty; heating element faulty; wiring faulty; PCB faulty. |

| E66 | Heating element power relay faulty (incongruence between sensing and relay) PCB faulty. |

| E68 | Current dispersion to earth (value of mains voltage different from main value) Current dispersion between between heating element and earth. |

| E69 | Heating element interrupted. Wiring faulty; Heating element for washing interrupted (thermofuse open) |

| E71 | Washing NTC sensor faulty (short- circuited or open) Wiring faulty; Washing NTC sensor faulty; PCB faulty. |

| E72 | Drying condenser NTC sensor faulty (voltage value out of limits, sensor short-circuited or open) Wiring faulty; Drying NTC sensor (condenser) badly positioned or faulty; WD board faulty. |

| E73 | Drying duct NTC sensor faulty (voltage value out of limits, sensor short-circuited or open) Wiring faulty; Drying NTC sensor (duct) badly positioned or faulty; WD board faulty. |

| E74 | Washing NTC sensor badly positioned. Wiring faulty; Washing NTC sensor badly positioned; NTC sensor faulty; PCB faulty. |

| E82 | Error in selector reset position. PCB faulty (Wrong configuration data). |

| E83 | Error in selector reading. PCB faulty (Wrong configuration data. |

| E91 | Communication error between PCB and display board. Wiring faulty; Control/display board faulty: PCB faulty. |

| E92 | Communication incongruence between main PCB- display board (versions not compatible) Wrong control/display board; Wrong PCB (do not correspond to the model). |

| E93 | Incorrect configuration of appliance. PCB faulty; (Incorrect configuration data). |

| E94 | Incorrect configuration of washing cycle. PCB faulty; (Incorrect configuration data). |

| E95 | Communication error between microprocessor and EEPROM. PCB faulty |

| E97 | Incongruence between programme selector and cycle configuration. Faulty PCB (Wrong configuration data). |

| E98 | Communication error between main board - Inverter. Incompatibility between main board and Inverter. |

| E9H | Communication error between microprocessor and FLASH memory. Display board. |

| E9C | Machine configuration error. Display board. |

| E9d | Clock faulty. Display board. |

| E9F | Communication error between PCB and remote devices. Wiring between PCB and Inverter faulty; PCB faulty; Inverter faulty. |

| EA1 | Drum positioning (DSP) faulty. Motor belt broken; Wiring faulty; PCB faulty; DSP sensor faulty. |

| EA6 | DSP door opening faulty. Motor belt broken; Wiring faulty; Drum cover open. Motor faulty; PCB faulty. |

| EC1 | Solenoid valve blocked with flowmeter working. Wiring faulty; Solenoid valve faulty/blocked, PCB faulty. |

| EC3 | Problems with Weight sensor (no signal or out of limits) Wiring faulty; Weight sensor faulty; PCB faulty. |

| Ed1 | Data communication error between WD board and PCB. Wiring faulty between PCB and WD board; WD board faulty; PCB faulty. |

| Ed2 | Drying heating element relay 1 faulty. Wiring faulty between WD board and thermostats; thermostats faulty; WD board faulty, PCB faulty. |

| Ed3 | Drying heating element relay 2 faulty. Wiring faulty between WD board and thermostats; thermostats faulty; WD board faulty, PCB faulty. |

| Ed4 | Relay which commutates power between washing heating element and drying (in the WD board). Wiring faulty; WD board faulty; PCB faulty. |

| Ed6 | No communication between PCB and display board (INPUT). Wiring faulty between PCB and programme display board; PCB faulty. |

| EF1 | Drain filter blocked (drain phase too long) Drain tube blocked/kinked/too high; Drain filter dirty/blocked. |

| EF2 | Excessive detergent dosing (excessive foam during draining) Excessive detergent dosing; drain tube kinked/blocked; Drain filter dirty/blocked. |

| EF3 | Aqua control intervention. Water leaks onto base frame; water control system defective. |

| EF4 | Water fill pressure low, no signal of flowmeter and solenoid valve open. Tap closed; water fill pressure low. |

| EF5 | Unbalanced load. Final spin phases skipped. |

| EF6 | Reset. No action to be performed, if continues replace the PCB. |

| EH1 | Frequency power of appliance out of limits. Power supply problems (incorrect / disturbance); PCB faulty. |

| EH2 | Voltage too high. Power supply problems (incorrect / disturbance); PCB faulty. |

| EH3 | Voltage too low. Power supply problems (incorrect / disturbance); PCB faulty. |

| EHF | Safety “sensing” circuit faulty (input voltage to microprocessor wrong) PCB faulty. |

| EHE | Incongruence between safety relay (in the PCB) and the safety “sensing” circuit. Wiring faulty; PCB faulty. |

Troubleshooting

Problem: The programme does not start.

Possible solution:

- Make sure that the mains plug is connected to the mains socket.

- Make sure that the appliance door is closed.

- Make sure that there is not a damaged fuse in the fuse box.

- Make sure that the Start/Pause has been touched.

- If the delay start is set, cancel the setting or wait for the end of countdown.

- Deactivate the Child Lock function if it is on.

Problem: The appliance does not fill with water properly.

Possible solution:

- Make sure that the water tap is open.

- Make sure that the pressure of the water supply is not too low. For this information, contact your local water authority.

- Make sure that the water tap is not clogged.

- Make sure that the inlet hose has no kinks, damages or bends.

- Make sure that the connection of the water inlet hose is correct.

- Make sure that the filter of the inlet hose and the filter of the valve are not clogged. Refer to ‘Care and cleaning’.

Problem: The appliance does not drain the water.

Possible solution:

- Make sure that the sink spigot is not clogged.

- Make sure that the drain hose has no kinks or bends.

- Make sure that the drain filter is not clogged. Clean the filter, if necessary. Refer to ‘Care and cleaning’.

- Make sure that the connection of the drain hose is correct.

- Set the drain programme if you set a programme without drain phase.

- Set the drain programme if you set an option which ends with water in the tub.

Problem: The spin phase does not operate or the washing cycle lasts longer than usual.

Possible solution:

- Set the spin programme.

- Make sure that the drain filter is not clogged. Clean the filter, if necessary. Refer to ‘Care and cleaning’.

- Adjust manually the items in the tub and start the spin phase again. This problem may be caused by balance problems.

Problem: There is water on the floor.

Possible solution:

- Make sure that the couplings of the water hoses are tight and there is not water leakages.

- Make sure that the water inlet hose and the drain hose have no damages.

- Make sure you use the correct detergent and the correct quantity of it.

Problem: You cannot open the appliance door.

Possible solution:

- Make sure that a washing programme that ends with water in tub, has been selected.

- Make sure that the washing programme is finished.

- Set the drain or the spin programme if there is water in the drum.

- Make sure that the appliance receives electrical power.

- This problem may be caused by a failure of the appliance. Contact the Authorised Service Centre. If you need to open the door, please read carefully «Emergency door opening»

Problem: The appliance makes an unusual noise and vibrates.

Possible solution:

- Make sure the levelling of the appliance is correct. Refer to ‘Installation instruction’.

- Make sure that the packaging and/or the transit bolts are removed. Refer to ‘Installation instruction’.

- Add more laundry in the drum. The load may be too small.