Ariston washing machine error codes serve as essential indicators for users to monitor their machine’s functionality. These codes offer rapid diagnostic insights, covering issues from water supply problems to electrical faults. Understanding and interpreting these error codes is crucial for users to efficiently troubleshoot and maintain their washing machines, ensuring prolonged and effective operation.

Codes Table

| Error Codes | Solution |

|---|---|

| F1 | Triac Short. Replace Control Board. |

| F2 | Main Motor. Check Main Motor connections. Replace Main Motor. Or, replace Control Board. |

| F3 | NTC (Water Temp) Open / Short. Check wiring continuity to Control Board. Replace NTC. Or, replace Control Board. |

| F4 | Pressure Switch. Check wiring continuity to Control Board. Replace Pressure Switch. Or, replace Control Board. |

| F5 | Blocked Drain Motor or Pressure Switch shorted in Empty position. Check Drain Hose. Check Drain Motor clean out for obstruction. Check voltage at Drain Motor. Check Pressure Switch wiring continuity. Replace Drain Motor / Pressure Switch. Or, replace Control Board. |

| F6 | Program Selector. Check wiring continuity to Control Board. Replace Program Selector. Or, replace Control Board. |

| F7 | Heater relay stuck. |

| F8 | Pressure Switch Shorted in Full Position. Check Pressure Switch wiring continuity. Or, replace Pressure Switch. Or, replace Control Board. |

| F9 | Control Board Error. Incorrect version of Control Board or EEPROM. Change Control Board and EEPROM. |

| F10 | Pressure Switch Shorted. Check wiring continuity to Control Board. Replace Pressure Switch. Or, replace Control Board. |

| F11 | Drain Motor. Check wiring continuity to Control Board. Check Drain Motor clean out for obstruction. Voltage check at Drain Motor. Check Pressure Switch. Replace Drain Motor. Or, replace Control Board. |

| F12 | No Communication Between Display and Control Board. Check Wiring Continuity. Voltage Check from Control Board to Display. |

| F13 | NTC (Dryer Temp) Open / Short |

| F14 | Dryer Heating Element is Open. Check Dryer Heating Element continuity. Check wiring from Element to Control Board. Replace Heating Element. Or, replace Control Board. |

| F15 | Dryer Heating Element Relay Shorted. Check Dryer Heating Element continuity. Check wiring from Element to Control Board. Replace Control Unit. |

| F16 | Extremely high water level Disconnect or turn off the water supply and ensure that the water level does not rise any more. |

| F17 | Door Open, or Door Lock Faulty. Check if Door is Closed. |

| F18 | 3 Phase Motor Control Faulty. Check Control Board. Change Control Board and EEPROM. |

| H20 | Not filling. Check tap, hose and inlet valves. |

| LOCKED | Check interlock. |

| F20/1 | The thermistor resistance has drifted or the temperature scanning sequence is incorrect. |

| F30/31 | A motor drive problem has occurred. |

| F40 | Water below protection level during a heat step. |

| F41 | Water level detect sequence incorrect. |

| F50/51 | Customer language and wash programme have not been saved. The system will run with default conditions (1000rpm max and English language). to re-programme your product. |

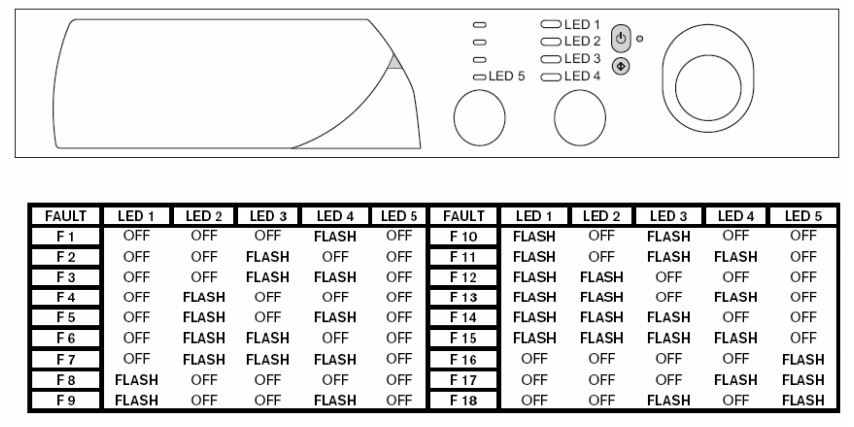

Flashing Lights

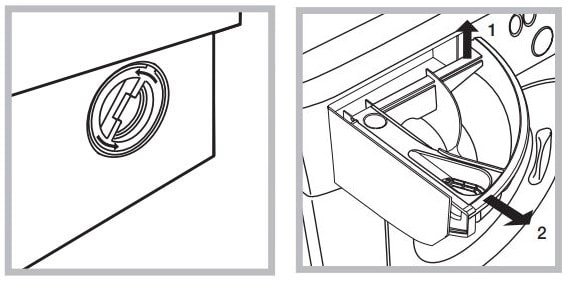

Cleaning the pump

The washing machine is fitted with a self-cleaning pump which does not require any maintenance. Sometimes, small items (such as coins or buttons) may fall into the pre-chamber which protects the pump, situated in its bottom part. Make sure the wash cycle has finished and unplug the appliance. To access the pre-chamber:

- unscrew the lid by rotating it anticlockwise (see figure): a little water may trickle out. This is perfectly normal;

- clean the inside thoroughly;

- screw the lid back on;

Checking the water inlet hose

Check the inlet hose at least once a year. If there are any cracks, it should be replaced immediately: during the wash cycles, water pressure is very strong and a cracked hose could easily split open. Never use second-hand hoses.

Description of the washing machine and starting a wash cycle

- Detergent dispenser drawer: used to dispense detergents and washing additives

- ON/OFF button: switches the washing machine on and off.

- WASH CYCLE knob: programmes the wash cycles. During the wash cycle, the knob does not move.

- FUNCTION buttons with indicator light: used to select the available functions. The indicator light corresponding to the selected function will remain lit.

- SPIN SPEED knob: sets the spin speed or exclude the spin cycle completely.

- TEMPERATURE knob: sets the temperature or the cold wash cycle.

- WASH CYCLE PROGRESS indicator lights: used to monitor the progress of the wash cycle. The illuminated indicator light shows which phase is in progress.

- DOOR LOCKED indicator light: indicates whether the door may be opened or not.

- START/PAUSE button with indicator light: starts or temporarily interrupts the wash cycles.

- N.B. To pause the wash cycle in progress, press this button; the corresponding indicator light will flash orange, while the indicator light for the current wash cycle phase will remain lit in a fixed manner. If the DOOR LOCKED indicator light is switched off, the door may be opened. To start the wash cycle from the point at which it was interrupted, press this button again.

- Standby mode This washing machine, in compliance with new energy saving regulations, is fitted with an automatic standby system which is enabled after about 30 minutes if no activity is detected. Press the ON-OFF button briefly and wait for the machine to start up again. Consumption in off-mode: 0,5 W Consumption in Left-on: 0,5 W

Troubleshooting

Your washing machine could fail to work. Before contacting the Technical Assistance Centre (see “Assistance”), make sure that the problem cannot be solved easily using the following list.

| Problem | Possible causes |

|---|---|

| The machine does not switch on. | The appliance is not plugged into the socket fully, or not enough to make contact. |

| There is no power to the socket, or the fuse has blown in the mains plug. | |

| The door is not closed properly. | |

| The ‘ON/OFF’ button has not been pressed. | |

| The ‘START/PAUSE’ button has not been pressed. | |

| The water tap has not been turned on to allow water to flow into the machine. | |

| A delayed start has been set. | |

| The machine does not fill with water or the indicator light for the first wash cycle stage flashes rapidly. | The water inlet hose is kinked. |

| The water inlet hose is not connected to the water supply. | |

| The water pressure is too low. | |

| The water tap has not been turned on to allow water to flow into the machine. | |

| There is no water supply to the house. | |

| The inlet valve filter is blocked. | |

| The ‘START/PAUSE’ button has not been pressed. | |

| The machine continuously fills with water and continually drains away or Water left in the dru or Stuck on wash. | The top of the drain hose is too low - It must be fitted at a height between 65 and 100 cm from the floor. |

| The drain hose is connected incorrectly to the sink trap allowing water to run into the machine, the drain hose must be positioned higher than the bottom of the sink to prevent water flowing down the drain hose. | |

| The end of the drain hose has been pushed too far down the standpipe, the ‘U’ bracket should be fitted 100 mm from the end of the drain hose. | |

| The machine does not drain or spin. | The Pump filter is blocked. |

| The drain hose is kinked. | |

| New Installation - The blanking cap or spigot has not been removed if connected under a sink. | |

| The drain hose or sink trap is blocked. | |

| The wash cycle does not include draining, some wash cycles require the drain phase to be started manually. | |

| The REDUCED CREASES function button has been activated. To complete the wash cycle, press the START/PAUSE button. | |

| The ‘Spin Speed’ selector knob is in the @ position. | |

| The programme takes too long. | Programme times will vary due to water pressure, the incoming water temperature and if the wash load goes out of balance. This will increase the programme times accordingly. |

| The machine vibrates a lot during the spin cycle. | The feet have not been adjusted, enabling the machine to rock. |

| New Installation - Either the Transit Bolts including the plastic spacers, or the Polystyrene Packaging have not been removed when installing the machine. | |

| The machine is trapped between cabinets and/or walls. | |

| The load is in a slight out of balance condition and machine is spinning, but at a lower speed. |