Bosch combi boiler fault codes provide crucial information for identifying issues in heating systems. These codes offer a quick overview of the device’s performance, aiding users in understanding potential problems. Accurate identification of combi faults can expedite repair processes and enhance energy efficiency. Bosch combi boiler fault codes enable timely intervention, contributing to the safer and more effective operation of heating systems.

Worcester Bosch Greenstar Codes

In the event that the appliance stops functioning or does not perform as expected, please see table below These problems are some of the most common causes. Should the problem persist or if other fault codes are displayed, then it will be necessary to contact Worcester, Bosch Group.

When calling Worcester, Bosch Group, you may be asked for the error code. This Table is for you to help identify

the possible cause of the fault.

- Do not try to rectify any of the faults listed below by yourself.

- Contact British Gas or a competent, qualified engineer (Gas Safe registered personnel)

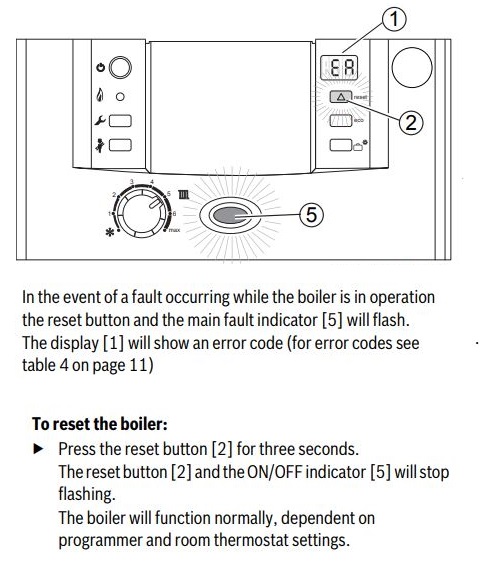

Press the reset button [2] for three seconds. The reset button [2] and the ON/OFF indicator [5] will stop flashing. The boiler will function normally, dependent on programmer and room thermostat settings.

If the fault cannot be cleared by pressing the reset button:

- Refer to the fault finding section on page 10 of these user instructions.

- Call Worcester, Bosch Group, giving a description of the fault and, if possible, the fault code from the seven segment display. Alternatively contact other Gas Safe registered personnel for assistance.

| Error Codes | Cause/Remedy |

|---|---|

| b1 | Code plug not detected. |

| C6 | Fan speed too low. |

| E9 | Safety temp. limiter in CH flow has tripped |

| EA | Flame not detected. If it safe to do so, check for:gas is on in the house, frozen condensate pipe, blocked flue outlet. |

| F0 | Internal error. |

| F7 | Flame detected even though boiler switched off. |

| FA | Flame detected after gas shut off. |

| Fd | Reset button pressed by mistake. |

| i1 | Current status. Appliance current operating status. |

| i2 | Previous status. Appliance previous operating status. |

| i3 | Maximum central heating output. Maximum central heating output (kW) set on the appliance. |

| i4 | Maximum domestic hot water output (kW). Maximum domestic hot water output (kW) set on the appliance. |

| i6 | Domestic hot water flow detected. A minimum flow rate of approximately 2.9 l/m has been detected by the appliance. YES = Flow detected. No = No flow detected. |

| i8 | Ionization current. Measured ionisation current (μA). |

| i9 | Flow temperature. Measured primary flow temperature of the appliance ( °C). |

| i11 | Domestic hot water outlet temperature. Measured DHW flow temperature of the appliance ( °C). |

| i12 | Domestic hot water set temperature. Displays the current set temperature for the domestic hot water. |

| i15 | Outdoor sensor. Temperature reading from outdoor temperature sensor, (only available if an outdoor sensor accessory is fitted) |

| i20 | CU version. Software version of the control box |

| i21 | HMI version. Software version of the HIS (Human Interface Software). |

| i22 | HCM version. Identification number of the HCM (Heating Control Module) and release version. |

| 200 | Central heating system is being heated. |

| 201 | Domestic hot water system is being heated. |

| 202 | Anti rapid cycle mode. The boiler has commenced anti-cycle period for CH. Can be adjusted in boiler settings (2.3b). Default 5 Minutes |

| 203 | System stand by. The appliance is waiting for the heating system to cool. |

| 204 | System waiting. |

| 208 | Appliance in service Test mode (Min/Max) |

| 260 | Sensor has been disconnected or there is no water content- check pressure gauge and repressurise to 1 bar |

| 265 | EMS intelligent controller has forced stan-by-mode due to low heating load. The appliance is compensating for the power required from the EMS room controller is less than the minimum output of the boiler). |

| 268 | Component test mode. Appliance is running the manual component test as activated in the menus. |

| 270 | Power up mode. (appliance is powering up). |

| 283 | Burner starting. The boiler prepares for a burner start. The fan and the pump are being controlled. |

| 284 | Gas valve(s) opened, flame must be detected within safety time. The boiler prepares for a burner start. The gas valve is being controlled. |

| 305 | Anti fast cycle mode (domestic hot water keep warm function). Diverter valve is held in hot water position for a period of time (determined by the software) after hot water demand |

| 309 | Central heating and domestic hot water system are being heated. |

| 357 | Appliance in air purge mode. Primary heat exchanger air venting program active - approximately 100 seconds. |

| 358 | Three way valve kick. If the 3-way valve hasn't moved in within 48 hours, the valve will operate once to prevent seizure. |

| 9A | Boiler has been fitted with incorrect Heat Control Module |

| 9U | The code plug could be faulty or not properly connected |

| B7 | You need to replace the control board |

| C6 | The system is running too fast or too slow |

| C7 | Fan is not running or the airflow could be blocked |

| D1 | Sensor could be wet, damaged or disconnected. The boiler will block for 300 seconds |

| D1 | Boiler is overheating |

| E2 | The Flow sensor has shorted, is damaged or disconnected |

| E5 | The primary flow sensor has overheated |

| A1 | Little or no water in the system- Check pressure gauge and re-pressurise to 1 bar |

| C1 | Fan has stopped |

| EF | The boiler is operating at minimum burner load and there is higher flow temperature of 18 degrees |

i1,i2,i3,..200,201,202… These are not faults, but provide information concerning the current status of the appliance. During normal appliance operation various Status codes can be displayed by pressing the info button. The first screen of the Information menu displays the current Status code, this will change as the appliance runs through the various modes and sequences.

Bosch Condens 2000 W Codes

| Failure Code on Display | Failure Descripton |

|---|---|

| 11 | MAP not selected (Fan speed adjustment according the flue pipe length). |

| A2 | Combustion chamber NTC failure (behind burner) : when the temperature by CC NTC reached to limit |

| A6 | Combustion chamber NTC failure (behind burner) : when NTC not detected or open circuit |

| A7 | Domestic hot water temperature sensor not correct installed or failure. |

| B3 -> d5 | Short circuit / failure in water level switch. |

| CE -> d4 | Gradient limit : Temperature rises too rapidly in heating mode |

| C7 | Fan sensor not detected. |

| C8 | Fan speed can not reached to target speed. |

| d7 | Modulator coil failure (regulator valve on gas valve) |

| EA | Ignition lock-out (flame not detected) (pump is running) |

| E2 | Flow temperature sensor failure (pump is running) |

| E9 | Overheat lock-out by temperatur limiters (STBs) (Flue gas + prim. Heatexchanger). In this case ; Heat demands is blocked and pump stops 3 min. later. |

| FA | Safety valve leaks. |

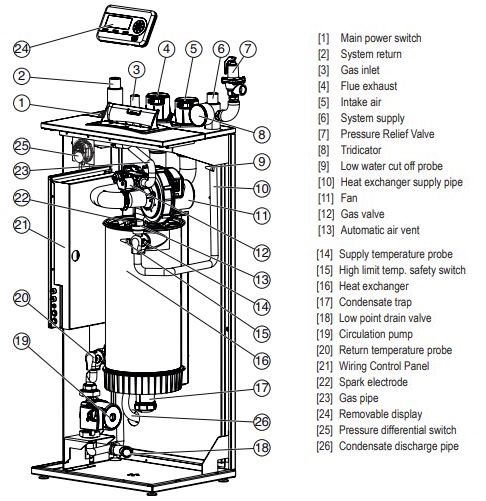

Bosch Gas Condensing Stainless Steel Boiler SSB Boiler Codes

Lockout Codes

If an error is a “Lockout” error, it is necessary to press “RESET” button (after eliminating the reason for the failure) to restart the boiler. In the following table the “Lockout” errors are listed:

| Error | Description |

|---|---|

| "Ignit Error" | Three unsuccessful ignition attempts in a row |

| "Gv Relay Error" | Failure detected in the GV (gas valve) Relay |

| "Gv Relay Not Open" | Failure detected in the GV (gas valve) Relay |

| "Gv Relay Not Close" | Failure detected in the GV (gas valve) Relay |

| "Safety Relay Error" | Failure detected in the Safety Relay |

| "Safety Relay Open" | Failure detected in the Safety Relay |

| "Safety Relay Closed" | Failure detected in the Safety Relay |

| "Blocking Too Long Error" | Control had a blocking error for more than 20 hours in a row |

| "Fan Error" | Fan MF deviation for more than 60 sec |

| "Ram Error" | Internal software error |

| "Wrong E2prom Signature" | Contents of E2prom is not up-to-date |

| "X Ram Error" | Internal software error |

| "E2Prom Error" | No communication with E2prom |

| "E2Prom Error C" | Wrong safety parameters in E2prom |

| "E2Prom Error Cal Table" | Wrong calibtration table parameters |

| "State Error" | Internal software error |

| "Rom Error" | Internal software error |

| "Rom Error C" | Internal software error |

| "Air Sw Not Open" | Air pressure switch not working |

| "15Ms Xrl Error" | Internal software error |

| "Air Sw Not Closed" | Air pressure switch not working |

| “Max. Thermostat Lock Error” | The external overheat protection is activated |

| "Stack Error" | Internal error |

| "Flame Out Too Late Error" | Flame still present 10 sec. after closing the gas valve |

| "Flame Error 1" | Flame is detected before ignition |

| "20Ms Xrl Error" | Internal software error |

| "41Ms Error" | Internal software error |

| "Too Many Flame Failures" | Three times flame lost during one demand |

| "Flow Switch Not Closed Error" | Flow switch not working / No flow |

| "Flow Switch Not Open Error" | Flow switch not working / No flow |

| "Flag Byte Integrity Error" | Internal software error |

| "Ad Hi Cpl Error" | Internal software error |

| "Ad Lo Cpl Error" | Internal software error |

| "Register Error" | Internal software error |

Blocking Codes

If an error is a “Lockout” error, it is necessary to press “RESET” button (after eliminating the reason for the failure) to restart the boiler. In the following table the “Lockout” errors are listed:

| Error | Description |

|---|---|

| "Ignit Error" | Three unsuccessful ignition attempts in a row |

| "Gv Relay Error" | Failure detected in the GV (gas valve) Relay |

| "Gv Relay Not Open" | Failure detected in the GV (gas valve) Relay |

| "Gv Relay Not Close" | Failure detected in the GV (gas valve) Relay |

| "Safety Relay Error" | Failure detected in the Safety Relay |

| "Safety Relay Open" | Failure detected in the Safety Relay |

| "Safety Relay Closed" | Failure detected in the Safety Relay |

| "Blocking Too Long Error" | Control had a blocking error for more than 20 hours in a row |

| "Fan Error" | Fan MF deviation for more than 60 sec |

| "Ram Error" | Internal software error |

| "Wrong E2prom Signature" | Contents of E2prom is not up-to-date |

| "X Ram Error" | Internal software error |

| "E2Prom Error" | No communication with E2prom |

| "E2Prom Error C" | Wrong safety parameters in E2prom |

| "E2Prom Error Cal Table" | Wrong calibtration table parameters |

| "State Error" | Internal software error |

| "Rom Error" | Internal software error |

| "Rom Error C" | Internal software error |

| "Air Sw Not Open" | Air pressure switch not working |

| "15Ms Xrl Error" | Internal software error |

| "Air Sw Not Closed" | Air pressure switch not working |

| “Max. Thermostat Lock Error” | The external overheat protection is activated |

| "Stack Error" | Internal error |

| "Flame Out Too Late Error" | Flame still present 10 sec. after closing the gas valve |

| "Flame Error 1" | Flame is detected before ignition |

| "20Ms Xrl Error" | Internal software error |

| "41Ms Error" | Internal software error |

| "Too Many Flame Failures" | Three times flame lost during one demand |

| "Flow Switch Not Closed Error" | Flow switch not working / No flow |

| "Flow Switch Not Open Error" | Flow switch not working / No flow |

| "Flag Byte Integrity Error" | Internal software error |

| "Ad Hi Cpl Error" | Internal software error |

| "Ad Lo Cpl Error" | Internal software error |

| "Register Error" | Internal software error |

| "WD Error Ram" | Internal software error |

| "WD Error Rom" | Internal software error |

| "WD Error Stack" | Internal software error |

| "WD Error Register" | Internal software error |

| "WD Error Xrl" | Internal software error |

| "Refhi Too Lo Error" | Internal software error |

| "Refhi Too Hi Error" | Internal software error |

| "Reflo Too Lo Error" | Internal software error |

| "Reflo Too Hi Error" | Internal software error |

| "Flame Error 2" | Flame is detected in a state in which no flame is allowed to be seen |

| "Water Level Detect" | Low water level detected |

| "Water Level Meas" | Low water level measurement error |

| "Low Water Cutoff Error" | Low water sensor error |

| "Low Water Pressure Error" | Low water pressure error |

| "Low Water Pressure Sensor" | Low water pressure |

| "Flue Gas Error" | Flue gas pressure error |

| "Return Temp Error" | Return temperature is higher than stay burning temperature |

| "Blocked Drain Error" | Block drain switch is active |

| "Wd Freq Error" | Incorrect Frequency signal or no communication with the WD |

| "Phase Error" | Hot neutral reversed |

| "Net Freq Error" | Net freq. error detected in the main |

| "Faulty Earth Error" | Faulty earth connection |

| "WD Communication Error" | Watchdog communication error |

| “Overheat Error” | Supply temp exceed the limit |

| "T Supply Open" | Supply sensor open |

| "T Return Open" | Return sensor open |

| "T Dhw Out Open" | DHW sensor open |

| "T Supply Shorted" | Supply sensor shorted |

| "T Return Shorted" | Return sensor shorted |

| "T Dhw Out Shorted" | DHW sensor shorted |

| "T Flue Shorted" | Flue sensor shorted |

| "Reset Button Error" | Reset button error |

| "Appliance Selection" | Appliance selection error |

| "Gas Pressure Error" | Gas pressure too low or too high |

| "Flue Press Error" | Flue gas pressure error |

Troubleshooting

| Trouble | Cause |

|---|---|

| Desired room temperature is not reached | Thermostatic radiator valve(s) set too low |

| Temperature control for central heating flow on appliance set too low | |

| Low temperature setting on the room thermostat | |

| Air trapped in heating system | |

| Low system water pressure | |

| Desired room temperature too high | Thermostatic radiator valves are set to high |

| Room thermostat is set too high | |

| Radiators are too hot | Temperature control on appliance set too high |

| Heating stays on for too long | Clock is incorrectly set |

| No blue Operation/Fault Indicator demand | Momentary power failure |

| Heat requirement demand operation light has been deactivated | |

| Hot water temperature too low | Temperature set too low on appliance controls |

| Water flow at tap too high | |

| Air trapped in heating system | |

| Low system water pressure | |

| Hot water temperature too high | Temperature set too high on appliance controls |

| Water flow at tap too low |

Manual Pdf

Worcester Bosch Greenstar Manual PDF

Bosch Condens 2000 W Manual PDF

Bosch Gas Condensing Stainless Steel Boiler SSB Boiler Manual PDF