Hisense is an electronics manufacturer based in China. The company is said to be the largest TV production house since 2004. Additionally, it offers a wide range of TVs under other brand names such as Toshiba, Sharp, Gorenje, Kelon, and Ornstein. Offering customers a wide range of selections so you can choose based on your preference. While every single one of them runs on similar systems.

The company’s largest product is televisions, and they offer other basic appliances such as ovens, mobile phones, smartphones, refrigerators, microwaves, and air conditioning systems. Offering residential and commercial customers a taste of what Hisense has to offer.

Hisense dishwashers are a reliable choice that can easily last for years to come. This is why when you see an error code we suggest you check the list below rather than guessing the error your dishwasher is showing.

Codes List

When some malfunctions happen, the appliance will display error codes to warn you.

| Error Codes | Solution |

|---|---|

| FA | Aquastop Failure. If the Aquastop contact on the bottom tray of the appliance is closed for mote than 30 seconds an Aquastop Failure will be detected. In an Aquastop condition, the Door will remain locked, and the Drain Pump will run constantly |

| F04 | Too Long Heat Time. If the water temperature is not increasing over 35C during 40 minutes of the first heating step in the cycle the CCU will display this Error. |

| F05 | Water Temperature Sensor Error. If during the water heating in the wash cycle, the water temperature sensor (NTC) value is out range, the ''F/05'' error code will be displayed. Check the water NTC resistance or Check connections to the NTC and CCU. |

| F06 | Drive Motor Tachometer Error. The control is unable to properly detect motor speed (several times) and the machine will shut down. If a failure occurs during high-speed spin the door will be unlocked after when the drum stops rotating. |

| F07 | Motor Control Triac Error. The main control has detected a short circuit in the motor control triac. If a failure occurs during high-speed spin the door will be unlocked after the drum has stopped rotating. Check CCU by running Test Program. |

| F08 | Heater Circuit Error. The main control has detected a heater circuit failure. This failure modes are checked before the cycle starts and after the spinning steps. |

| F12 | Heater Circuit Error. The main control has detected a heater circuit failure. This failure modes are checked before the cycle starts and after the spinning steps. |

| F13 | Door Open LED flashing after the cycle is started. If the CCU is not able to lock the Door of the washer after program start within 10 the Door Open LED will flash for 10. |

| F14 | EEPROM Error. The Central Control Unit (CCU) receives it's data from an EEPROM onboard the CCU. If there is an error reading this data it will cause this error. |

| F15 | Drum Up Circuit Missing ( Only for TOPLOADERS with DRUM UP Circuit). If the CCU is not detecting the Drum Up switch closing during Motor rotation this failure is displayed. This Error is detected ONLY during the Service Program. |

| F21 | User Interface Error ( detected only with Smart user interfaces). If the communication between user interface module and CCU is disturbed this Error is displayed. If the failure is displayed on the digits the display module is not able to ''talk'' to the CCU. Iff the failure is displayed on the status LED the CCU is not able to contact the Dİsplay module. |

| F23 | Pressoswitch Failure. If the CCU is detects during the wash cycle that the pressowich contact for the wash level and the pressoswitch level for the heater safety are ON simultanouslt for 10'' this failure will be displayed. |

| F24 | OverFlow Failure. If the Overflow contact on the pressure switch is Closed for more than 60 seconds an Overflow condition will occur. In an Overflow condition, the Door will remain locked, and the Drain Pump will run constantly. |

| F26 | Pump Driver Failure. If the CCU detects during the wash cycle that the triac of the pump is defective it will display this failure. Check the resistance of the pressoswitch contacts. |

| F27 | Reversing relay failure. If the CCU detects that the motor is possible to rotate only in one direction this failure is displayed. Check the CCU. |

| F28 | Tapped Filed Failure. If the CCU is not able to switch ON the tapped field of the Motor this failure Code is displayed. |

| Fod | Foam detected During the Wash Cycle. If the CCU is not able to drain out the water after washing or not able to spin after several trial this alarm Code is displayed. |

| UnB | Unbalance Error. Cause: The load is to small. The appliance is tilted. Laundry is gathered to one side. Non distributable things are put into the drum. |

In case of any abnormal conditions are detected during running, turn off all loads except for door lock, and then the buzzer sounds to give an alarm.

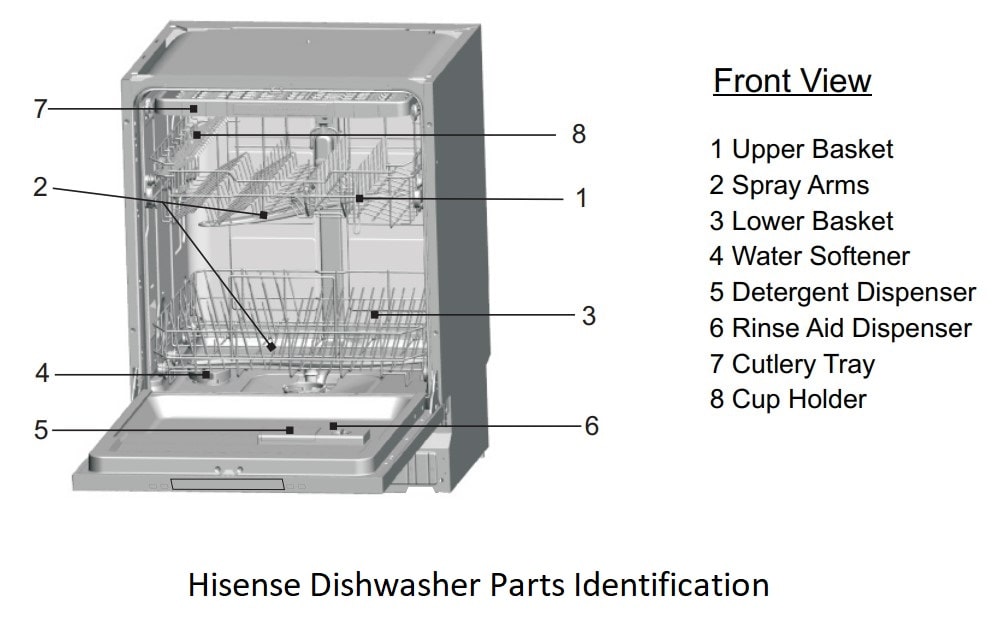

Parts Meaning

Troubleshooting

Depending on the model, your washing machine is equipped with various automatic safety functions. This enables faults to be detected in good time and the safety system can then react appropriately. These faults are frequently so minor that they can be resolved within a few minutes.

The washing machine will not start, no screen are off.

- the mains plug is inserted into the socket and Choose the desired programmme to start the machine.

- the wall socket is functioning correctly (use a table lamp or similar appliance to test it).

The washing machine will not start, and the screen flashes.

- the door is properly closed (child safety);

- the “Start/Pause” button has been pressed;

- Check If the water tap Is closed. Open the water tap and press the “Start/Pause” button.

The appliance stops during the programme (varies depending on model)

- the ”Rinse Hold” indicator lamp lights up; terminate this option by pressing the “Start/Pause” button or by choosing and starting the “Drain” programme;

- the screen is flashing. Press the ‘Start/Pause” button.

- the door has been opened and the screen is flashing. Close the door and press the ‘Start/Pause’ button again.

- Check if there is too much foam inside. machine enters kill-foam routine. The machine will run again automatically after a period.

- the washing machine’s safety system has been activated.

Machine vibrates during spin cycle.

- the washing machine is level and standing firmly on all four feet;

- the transport belts have been removed. Before using the machine, it is imperative that the transport bolts are removed.

Final spin results are poor.

- If the laundry is still too wet at the end of the cycle, remove some articles of laundry and repeat the spin cycle.

- Excessive foam formation may prevent spinning. Use the correct amount of detergent.

- Check that the spin speed selector has not been set to ”0”.

If the fault occurs again, please contact After-Sales Service.