Westinghouse washing machines come with various error codes that users may encounter. These error codes are crucial for monitoring the machine’s operation and swiftly diagnosing issues. They enable users to optimize the machine’s performance and ensure long-lasting functionality. Understanding and appropriately addressing these error codes is essential for Westinghouse washing machine owners to use their appliances efficiently and trouble-free.

Most Common Codes

| Error Codes | Solutions |

|---|---|

| E11 | Water fill difficulty during washing. Tap closed or water pressure too low; Drain pipe improperly positioned; Water fill solenoid valve faulty; Leaks from water circuit on pressure switch; Pressure switch faulty; Wiring faulty; Main PCB faulty. Cycle is paused with door locked. |

| E12 | Water load problems during drying cycle. Water tap closed or water flow too low; Wrong drain pipe position; Water inlet valve defective; Air trap system leaking; Pressure switch defective; Wiring or main board defective. Cycle Paused with door locked |

| E13 | Water leaks. Drain pipe improperly positioned; Water pressure too low; Water fill solenoid valve faulty; Water circuit on pressure switch is leaking/clogged; Pressure switch faulty. Cycle is paused with door locked. |

| E21 | Drain difficulty during washing. Drain pipe kinked/clogged/improperly positioned; Drain filter clogged/dirty; Wiring faulty; Pressure switch faulty; Drain pump rotor blocked; Drain pump faulty; Main PCB faulty. Cycle paused (after 2 attempts). |

| E22 | Water drain problems during drying cycle. Drain pipe blocked up; Blocked/dirty filter; Drain pump defective; Pressure switch defective; Wiring or main Board defective. Cycle Paused. |

| E23 | Faulty TRIAC for drain pump. Wiring faulty; Drain pump faulty; Main PCB faulty. Safety drain cycle - Cycle stops with door open. |

| E24 | Drain pump TRIAC “sensing” circuit faulty. Main circuit board faulty. Safety drain cycle - Cycle stops with door unlocked. |

| E25 | Aqua control sensing failure. Main board defective. Safety Drain cycle. Cycle stops with door unlocked. |

| E31 | Electronic pressure switch circuit faulty. Wiring; Electronic pressure switch; Main PCB; Cycle stops with door locked. |

| E32 | Calibration error of the electronic pressure switch. Drain tube kinked/clogged/improperly positioned; Faulty solenoid; Drain filter clogged/dirty; Drain pump faulty; Leaks in the pressure switch hydraulic circuit; Pressure switch faulty; Wiring; main PCB. Cycle paused. |

| E35 | Overflow. Water fill solenoid valve faulty; Leaks from water circuit on pressure switch; Wiring faulty; Pressure switch faulty; Main PCB faulty. Cycle interrupted. Safety drain cycle. Drain pump continues to operate (5 min. on, then 5 min. off. etc.) |

| E38 | Internal pressure chamber is clogged (water level does not change for at least 30 sec. of drum rotation). Motor belt broken; Water circuit on pressure switch clogged. Heating phase is skipped. |

| E41 | Door open. Check whether the door is closed properly; Wiring faulty; Door safety interlock faulty; Main circuit board faulty. Cycle paused. |

| E42 | Problems with door lock. Wiring faulty; Door safety interlock faulty; Electrical current leak between heating element and ground; Main PCB faulty. Cycle paused. |

| E43 | Faulty TRIAC supplying power to door delay system. Wiring faulty; Door safety interlock faulty; Main circuit board faulty. (Safety drain cycle) Cycle blocked. |

| E44 | Faulty sensing by door delay system. Main circuit board faulty. (Safety drain cycle) Cycle blocked. |

| E45 | Faulty sensing by door delay system TRIAC. Main circuit board faulty. (Safety drain cycle) Cycle blocked. |

| E51 | Motor power TRIAC short-circuited. Current leakage from motor or from wiring; Main PCB faulty. Cycle stops with door open (after 5 attempts) |

| E52 | No signal from motor tachometric generator. Wiring faulty; Motor faulty; Main circuit board faulty. Cycle stops with door locked (after 5 attempts) |

| E53 | Faulty sensing by motor TRIAC. Main circuit board faulty. Cycle blocked. |

| E54 | Motor relay contacts sticking. Current leakage from motor or from wiring; Main PCB faulty. Cycle blocked (after 5 attempts) |

| E61 | Insufficient heating during washing. Wiring faulty; NTC probe for wash cycle faulty; Heating element faulty; Main PCB faulty. The heating phase is skipped. |

| E62 | Overheating during washing (temperature higher than 88°C for more than 5 min.) Wiring faulty; NTC probe for wash cycle faulty; Heating element faulty; Main PCB faulty. Safety drain cycle Cycle stops with door open. |

| E66 | Heating element power relay faulty (inconsistency between sensing and relay status) Main PCB faulty; Safety water fill Cycle stops with door closed. |

| E68 | Earth leakage. Earth leakage between heating element and earth. The heating phase is skipped. |

| E69 | Heating element interrupted. Wiring faulty; Heating element for washing interrupted (thermal fuse open); Main circuit board faulty. |

| E6A | Heating relay sensing faulty. Main circuit board faulty. Cycle stops with door locked. |

| E6B - E6H | Heating element power relay faulty (inconsistency between sensing and relay status) Wiring faulty; Earth leakage between heating element and earth; Main PCB faulty. Safety water fill Cycle stops with door closed. |

| E71 | NTC probe for wash cycle faulty (short-circuited or open) Wiring faulty; NTC probe for wash cycle faulty; Main circuit board faulty. The heating phase is skipped. |

| E72 | Output drying NTC failure. Output drying NTC defective; Wiring or WD board defective. Drying heating phases skipped. |

| E73 | Input drying NTC failure. Input drying NTC defective; Wiring or WD board defective. Drying heating phases skipped. |

| E74 | NTC probe for wash cycle improperly positioned. Wiring faulty; NTC probe for wash cycle improperly positioned; NTC probe faulty; Main PCB faulty. The heating phase is skipped |

| E83 | Error in reading selector. Main PCB faulty (incorrect configuration data). Cycle cancelled. |

| E84 | Recirculation pump / Motor fan triac sensing failure. Main board defective. Safety Drain cycle. Cycle stops with door unlocked. |

| E85 | Recirculation pump / Motor fan triac alarm. Recirculation pump or motor fan defective; Wiring or main board defective. Safety Drain cycle. Cycle stops with door unlocked. |

| E86 | Selector configuration error. Display board. |

| E87 | Display board microprocessor faulty. Display board. No action to be taken. |

| E91 | Communication error between main PCB and display. Wiring faulty; Control/display PCB faulty; Main circuit board faulty. |

| E92 | Communication inconsistency between main PCB and display (incompatible versions) Incorrect control/display PCB; Incorrect PCB (does not correspond to the model). Cycle blocked. |

| E93 | Appliance configuration error. Main PCB faulty (incorrect configuration data). Cycle blocked. |

| E94 | Incorrect configuration of washing cycle. Main PCB faulty (incorrect configuration data). Cycle blocked. |

| E97 | Inconsistency between programme selector and cycle configuration. Main PCB faulty (incorrect configuration data). Cycle blocked. |

| E98 | FCV_MB protocol incong. Error. Main board incompatible with FCV control board. Cycle blocked. |

| E9C | Display board configuration error. Display board faulty. |

| E9E | UI touch fault. Display Board. No actions. |

| EA1 | DSP system failure. Wiring or main board defective; DSP sensor failure; Main motor belt broken. Skip of the drum positioning phase. |

| EA6 | DSP door open failure. Wiring or main board defective; DSP sensor failure; Main motor belt broken; Lid open. Cycle paused. |

| EB1 - EH1 | Power supply frequency out of limits. Wrong or disturbed Power Supply line. Main board defective. Wait for nominal power supply conditions. |

| EB2 - EH2 | Power supply voltage too high. Wrong or disturbed Power Supply line. Main board defective. Wait for nominal power supply conditions. |

| EB3 - EH3 | Power supply voltage too low. Wrong or disturbed Power Supply line. Main board defective. Wait for nominal power supply conditions. |

| EB4 - EH4 | Zero Watt relay alarm. Main board defective. No actions. |

| EBD - EHD | Heater WD relay sensing alarm. Main board defective. Cycle blocked with door locked. |

| EC1 | Electronically controlled valve blocked with operating flow meter. Faulty wiring; Faulty/blocked solenoid, PCB faulty. Cycle stops with door locked Drain pump continues to operate (5 min. on, then 5 min. off. etc.) |

| EC4 | AGS current sensor faulty. Main board faulty. Spin speed reduced to safety speed of 150 rpm. |

| ED1 | WD board communication alarm. WD board defective; Wiring between MB and WD, Main Board defective, UI defective, Weight defective, FCV defective. Cycle blocked. |

| ED2 | WD heating element1 relay failure. WD board defective; wiring, thermostats defective; Main Board defective. Skip drying phase. |

| ED3 | WD heating element1 sensing relay failure. WD board defective. Skip drying phase. |

| ED4 | WD heating element2 relay failure. WD board defective; wiring, thermostats defective, Main Board defective. Skip drying phase. |

| ED5 | WD heating element2 sensing relay failure. WD board defective. Skip drying phase. |

| ED6 | WD thermostat sensing failure. WD board defective. No actions. |

| ED7 | WD thermostat failure. Manual or automatic; thermostat opened, wiring , WD board defective. No actions. |

| ED8 | WD fan motor tachometer absent. Fan Motor defective Fan Motor Wiring or WD board defective. Skip drying phase. |

| ED9 | WD fan motor driving circuit alarm. WD board defective. Skip drying phase. |

| EDA | WD Power Supply alarm. Wrong or disturbed Power Supply line. WD board defective. Wait for nominal power supply conditions. |

| EDB - EDH | WDM microcontroller fault. WDM board defective. No actions to be performed. If still present replace the WDM Board. |

| EDC | WDM heating element opened. Drying heating elements opened, unplugged, or wiring. No actions. |

| EDD | WDM Ground Current leakage alarm. Current leakage between drying heater element and earth. Drying phases skipped. |

| EF1 | Drain filter clogged (drain phase too long) Drain filter clogged/dirty; Drain hose blocked/kinked/too high. Warning displayed at the end of cycle. |

| EF2 | Overdosing of detergent (too much foam during drain phases) Excessive detergent dosing; Drain hose kinked/blocked; Drain filter clogged/dirty. Warning displayed after 5 attempts or by the specific LED |

| EF3 | Aqua control system intervention. Water leaks onto base frame; Aqua control system faulty; Drain pump coil overheating/broken. Appliance drains. |

| EF4 | Water fill pressure too low, no signal from flow meter and electronically controlled valve is open. Tap closed, water fill pressure too low. |

| EF5 | Unbalanced load. Final spin phases skipped. |

| EF6 | Reset. If it continues, replace the main board. No action to be taken. |

| EH1 | Power supply frequency of appliance outside the limits. Problem with the power supply network (incorrect/disturbed); Main PCB faulty. Wait for nominal frequency conditions. |

| EH2 | Supply voltage too high. Problem with the power supply network (incorrect/disturbed); Main PCB faulty. Wait for nominal voltage conditions. |

| EH3 | Supply voltage too low. Problem with the power supply network (incorrect/disturbed); Main PCB faulty. Wait for nominal voltage conditions. |

| E01 | The door of your machine is left open. Close the machine door. If your machine persists to indicate fault, turn off your machine, unplug it and contact the nearest authorised service immediately. |

| E02 | The water pressure or the water level inside the machine is low. Turn on the faucet. Mains water may be cut-off. If the problem still continues, your machine will stop after a while automatically. Unplug the machine, turn off your faucet and contact the nearest authorised service. |

| E03 | The pump is faulty or pump filter is clogged or electrical connection of the pump is faulty. Clean the pump filter. If the problem persists, contact the nearest authorised service. |

| E04 | Your machine has excessive amount of water. Your machine will discharge water by itself. Pursuant to discharging operation, turn off your machine and unplug it. Turn off your faucet and contact the nearest authorised service. |

| Err 1 | Indicator: The start/pause light blinks. Probable:The door is not shut properly. Shut the door properly so that you hear the click. If the problem persists, turn off the machine unplug and apply to the nearest authorized service immediately. |

| Err 2 | Indicator: The program ready light blinks. Probable: The water level in your machine is below heater. The pressure of your water supply may be low or locking. |

| Err 3 | Indicator: The start/pause light and program ready light blinks. Probable: The pump has failed or the pump filter is obstructed. Clean the pump filter. If the problem persists,apply to the nearest authorized service. |

| Err 4 | Indicator: The program end light blinks. Probable: Communication error. Shut down your machine and unplug. Turn off your tap and apply to the nearest authorized service. |

| Err 5 | Indicator: The start/pause light and program end light blink. Probable: The heater of your machine or the heat sensor has failed. |

| Err 6 | Indicator: The program ready light and program end light blink. Probable: The motor has failed. |

| Err 7 | Indicator: The program start/pause light, ready light and program end light stays on permanently. Probable: Configuration error. |

| Err 8 | Indicator: The start/pause light,program ready light and program end light blink. Probable: Fault error. Shut down your machine and unplug. Turn off the tap and apply to the nearest authorized service. |

| Err 9 | Indicator: The program ready light and program end light stays on permanently. Probable: The network voltage is too high or too low. If the network voltage is lower than 150V or higher than 260V, your machine will automatically stop. When the network voltage is recovered, your machine will continue its operation. |

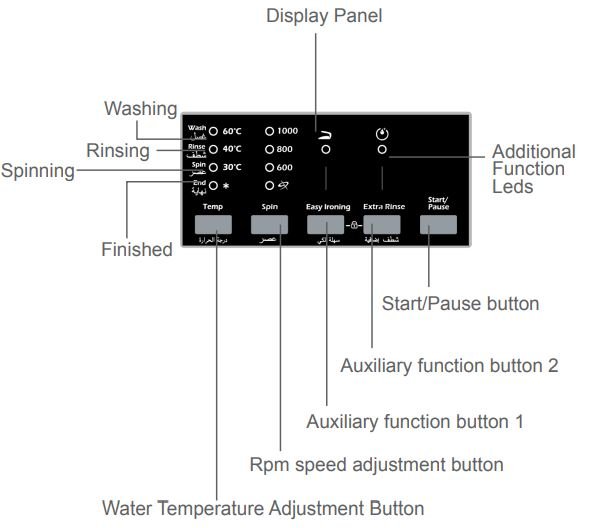

Control Panel and Display

Maintenance and Cleaning

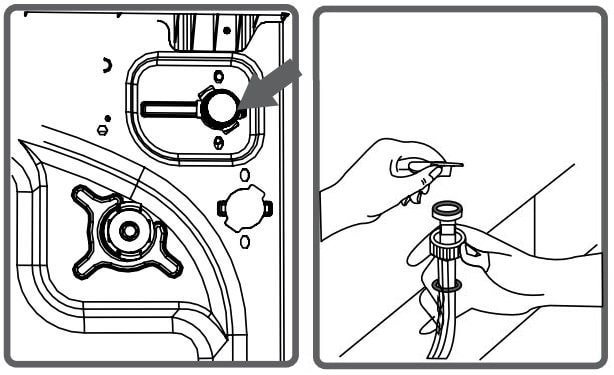

Water Inlet Filters

Filters to avoid dirt and foreign substances in the water from penetrating into the machine are available both on the side of faucet and on the ends of water valves along the water inlet hose of your machine. If your machine cannot intake sufficient amount of water despite water faucet being open, these filters should be cleaned.

(It is recommended that you clean your pump filter once in 2 months.)

- Detach the water inlet hoses.

- Remove the filters on water inlet valves using pliers and then clean it with a brush in water.

- Disassemble the filters on the side of faucet side of water inlet hoses manually and clean it.

- Having the filters cleaned, you can fit them in the same way reversely.

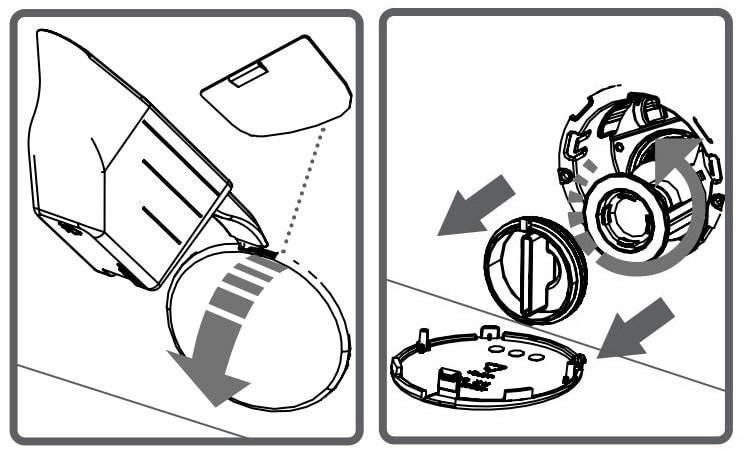

Pump Filter

A filter system which avoids threads remaining from your laundries and tiny materials from entering into the pump during water discharging operation carried out by your machine after completing washing so prolonging the life cycle of your pump is available. It is recommended that you clean your pump filter once in 2 months. To clean pump filter:

- To open the pump cover, you can use the powder detergent spade or liquid detergent level plate coming out of your machine.

- Fit the end point of the plastic part to the gap of the pump cover and push it back. This will open the cover.

- Before opening the filter cover, settle a vessel in front of the filter cover to prevent the water remained in the machine from flowing on the ground.

- Loosen the filter cover in counter-clockwise and then empty water.

Troubleshooting

| Fault | Possible Cause |

|---|---|

| Your machine does not start. | It is not plugged. Plug it. |

| Fuse blown. Replace the fuses. | |

| Electricity cut-off. Check mains power. | |

| Start/pause button not pressed. Press on Start/ Pause button. | |

| Programme dial ‘stop’ position. Switch the programme button to the desired position. | |

| The machine door is not completely closed. Close the machine door. | |

| Your machine does not intake water. | Water tap is turned off. Turn your faucet on. |

| Water inlet hose may be twisted. Check water inlet hose and untwist. | |

| Water inlet hose clogged. Clean water inlet hose filters. | |

| Valve inlet filter clogged. Clean the valve inlet filters. | |

| The machine door is not completely closed. Close the machine door. | |

| Your machine does not discharge water. | Discharging hose clogged or twisted. Check the discharg- ing hose, then either clean or untwist. |

| Pump filter clogged. Clean the pump filter. | |

| Laundry settled in the machine unevenly. Spread your laundries in the machine properly and homogeneously. | |

| Your machine vibrates. | The feet of your machine have not been adjusted. Adjust the feet on your machine. |

| Safety stays fitted for transportation not disassembled. Disassemble the safety stays of your machine. | |

| Less amount of laundry in the appliance. This will not block operation of your machine. | |

| Your machine is overloaded with laundry or laundry settled unevenly. Do not put in laundry more than the amount recom- mended and settle the laundry in the machine evenly. | |

| Your machine rests on a hard surface. Prevent your ma- chine from resting on hard surfaces. | |

| Excessive foam is formed in the detergent drawer. | Excessive amount of detergent used. Press on Start/Pause button. To eliminate foam formation, mix a spoon of softener with half litres of water, and pour the mixture in the detergent drawer. After 5-10 minutes, press on Start/ Pause button again. In your next washing operation, Adjust the detergent dose accordingly. |

| Wrong detergent used. Use detergents produced only for automatic washing machines in your machine. | |

| Unsatisfactory washing result. | The contamination degree of your laundries does not match the programme you have chosen. Select the programme appropriate for the contamination degree of your laundries. |

| Amount of detergent used insufficient. Adjust the amount of detergent based on the amount and contamination degree of your laundries. | |

| Laundries in excess of maximum capacity put in your machine. Load your machine with laundries, amount of which will not exceed maximum laundry capacity. | |

| Unsatisfactory washing result. | Water being hard. Adjust the amount of detergent based on the instruction of detergent manufacturer. |

| Laundries distributed in your machine nonhomogenously. Spread your laundry in the machine evenly. | |

| As soon as the machine is loaded with water, water discharges. | The end of water discharging hose is too low for the machine. Set the water discharging hose on appropriate height. |

| No water appears in the drum during washing. | No fault. Water is in the unseen part of the drum. |

| Laundries have detergent residues on them. | Non-dissolving particles of some detergents may stick to your laundries as white spots. Perform an extra rinsing by setting your machine to “Rinsing” programme, or clean the spots using a brush after your laundries dry. |

| Grey spots appear on the laundries. | The reason for such spots may be oil, cream or ointment. Apply the maximum amount of detergent instructed by the detergent manufacturer in the next washing operation. |

| Spinning operation is not performed or runs late. | No fault. Unbalanced load control system has been activated. Unbalanced load control system will try to spread your laundries homogeneously. Wringling operation will begin after your laundry is spread. Place the laundry in the machine in a balanced fashion the next time. |

Manual Pdf

Westinghouse Washing Machine Manual PDF – Model: WWF8025DQWA

Westinghouse Top-load Washing Machine Manual PDF – Model: WWT6084J5WA